Woods makes hundreds of different subframes for many many tractors.

This is one of the reasons that the makers of the Prairie Dog hoe copied

the structure of the Woods 7500. The earlier subframes sold by Woods

were of the ladder type, and they often required you to mount brackets

to the tractor carcass that blocked off the 3-pt hitch lower lift arms. This

made it very tough to use the 3PH when the hoe was dismounted. The

ladder frames also extended very far to the rear; I suspect that was to

provide clearance for the seat. Woods did not optimize their subframes

for the closest possible hoe mount. Some of Woods' subframes for

different tractors are so similar that I suspect that they also tried to

minimize how different each one was to limit manufacturing costs. Kind

of like a "least common denominator" approach to design. A custom subframe

can improve that by optimizing for a particular tractor.

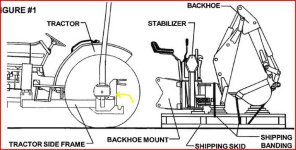

As a point of reference, an integrated TLB will have a departure angle of

as much as 20 degrees; an attachment subframe is rarely better than 15

degrees.

I have purchased and installed only one Woods factory subframe (on the

L2550 above), and I found the price to be reasonable (about $500), but

the wait was very long. Their newer 4-pt subframes are over $1000.

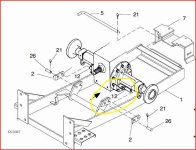

The pix show Woods 4-pt subframes for Kubota L-series and B-series. In

the latter case, you can see that the subframe does not have a structural

member that wraps around the rear axles. Lack of clearance is the likely

reason. I like how robust these units are, and their use of existing threaded

holes in the Kubota castings where possible. (Note that Kubota and

Kioti have many unused threaded holes available on their tractors, while JD

has few. I don't know about other tractor brands.)

It is also interesting how Woods' design strategies have evolved. Newer

subframes no longer block the 3PH, and earlier pinned connections are

often replaced with secured bolts. They even provide a wrench to help

speed up the mount/dismount process (3rd photo). These last 2 photos

and the first one show Kubota Grand L 4-pt subrames.

Pin attachments are quick to install or remove, but they wiggle. Bolts are

more secure, but they can loosen up and they take longer to attach

and remove. Any slop in rigid mounts will allow wear in the holes. Bradco

attempts to find the best of both worlds, with pins and wedges.