MountainBuck

Silver Member

Today I had a very difficult time connection the "quick disconnect" fittings on the bucket to my 4500p.

None of the 4 hoses would not connect.

I then wondered if pressure in the bucket hoses was too high, so I pushed in the pin with great difficulty on the hoses to relieve the pressure.

Then it was easy to connect.

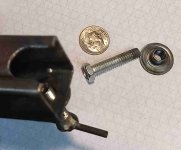

So I was wondering if there is a tool available to push in this pin? I cannot think of anything else to relieve the pressure short of taking a wrench to unscrew the fitting.

By the way, pushing in this pin is very dangerous due to the high pressure it was under. It also took all of the hand strength I could muster.

None of the 4 hoses would not connect.

I then wondered if pressure in the bucket hoses was too high, so I pushed in the pin with great difficulty on the hoses to relieve the pressure.

Then it was easy to connect.

So I was wondering if there is a tool available to push in this pin? I cannot think of anything else to relieve the pressure short of taking a wrench to unscrew the fitting.

By the way, pushing in this pin is very dangerous due to the high pressure it was under. It also took all of the hand strength I could muster.