oldnslo

Super Member

Rd

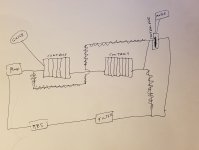

Pump cavitation is when the pump is drawing air on the suction side and when pump is attempting to build pressure this cavitation creates noise and destroys the pump.

power beyond is the term for an open center valve where flow exits the valve and can be used to power equipment down stream. On 99 percent of mobile valves you cannot pressurize the tank or return line

closed center valves do not require a power beyond.

from what I am reading in your posts you do not appear to know what type or size of pump was on this machine originally and or what style of valves you have.

my suggestion is to figure out what style system you have before you damage something

Pump cavitation is when the pump is drawing air on the suction side and when pump is attempting to build pressure this cavitation creates noise and destroys the pump.

power beyond is the term for an open center valve where flow exits the valve and can be used to power equipment down stream. On 99 percent of mobile valves you cannot pressurize the tank or return line

closed center valves do not require a power beyond.

from what I am reading in your posts you do not appear to know what type or size of pump was on this machine originally and or what style of valves you have.

my suggestion is to figure out what style system you have before you damage something