J_J

Super Star Member

- Joined

- Sep 6, 2003

- Messages

- 18,973

- Location

- JACKSONVILLE, FL

- Tractor

- Power-Trac 1445, KUBOTA B-9200HST

Whats a controlled interference fit?

Also, JJ you mentioned I would need to have a connector machined? Any chance they allready exist?

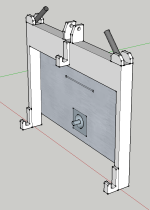

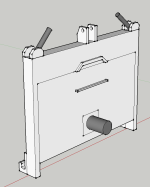

Carl, You could use something that PT already has, if the taper is the same. Most of the wheel motors I have seen use 1 1/4 tapered or 1 1/2 in tapered shaft. There may be some adapters out there to go from say 1 1/4 tapered to a 1 in female adapter to fit the auger shaft. I would at least take a drawing to a machine shop and get an estimate for the adapter. You may need a different adapter for each implement you want to use. In the picture I sent above, the hydraulic motor just happens to fit the shaft of the implement, which is a neat setup for 3PT implements. If you are starting from scratch, you can specify the hydraulic motor to match something you already have, be it tapered,straight, or splined.

http://www.northerntool.com/webapp/...=mode+matchallpartial&Dx=mode+matchallpartial

These are some adapters used on tractors. You would need to show and explain what you are trying to do.

Last edited: