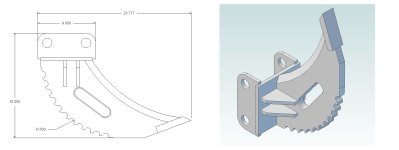

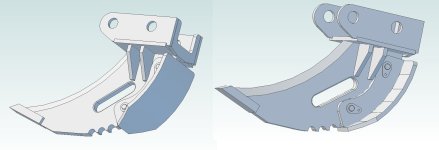

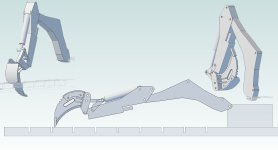

I've just completed the first pass design for a backhoe ripper I'm getting ready to build. I would like opinions on it before I go into production. The goal is to build a better ripper than the brotek that everyone seems to be using for the JD 260 backhoe. I want to be able to cut through roots up to 8" in diameter. To do this I have added large teeth on the back side, a tool steel tooth on the bottom, and a 60 degree knife edge on the front. The pin dimensions may have to be altered some. The mounting ears are 1/2" mild steel and the ripper shank is 1" thick. I did not draw the pin bushings yet because I haven't taken any measurements from my backhoe. It's currently at a job site.

I put a cutout in the middle to give myself something to grab onto that wouldn't be sharp while installing or moving it I think it will weigh about 100 lbs when finished.

I think it will weigh about 100 lbs when finished.

I put a cutout in the middle to give myself something to grab onto that wouldn't be sharp while installing or moving it