RDrancher

Veteran Member

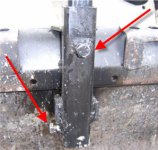

I'm going to weld up a removable laser receiver mast for my CTL similar to this. Mine will differ slightly since I will be welding the bracket to the back of the bucket.

There's a complete description of what's needed here SKID STEER BUCKET MOUNTING. Basically it's a 1.5" square tube for the mast and a 2" tube for the welded on bracket.

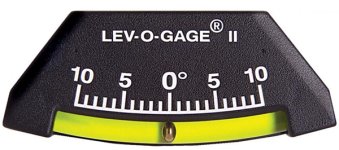

I'll also be making a setup for my box blade, except it will be a straight mast above the blade. What I can't wrap my head around is how to make it adjustable if I'm cutting a v-shaped drainage swale with the box blade angled (tilted.) I can setup the laser to detect the desired slope of the swale, but the receiver needs to be (somewhat) plumb. I'd like it to be infinitely adjustable for plumb, but a vertical and two off-vertical settings would be fine. Keep in mind that I always cut swales with the right side of the box blade lower than the left.

Any ideas?

There's a complete description of what's needed here SKID STEER BUCKET MOUNTING. Basically it's a 1.5" square tube for the mast and a 2" tube for the welded on bracket.

I'll also be making a setup for my box blade, except it will be a straight mast above the blade. What I can't wrap my head around is how to make it adjustable if I'm cutting a v-shaped drainage swale with the box blade angled (tilted.) I can setup the laser to detect the desired slope of the swale, but the receiver needs to be (somewhat) plumb. I'd like it to be infinitely adjustable for plumb, but a vertical and two off-vertical settings would be fine. Keep in mind that I always cut swales with the right side of the box blade lower than the left.

Any ideas?