Shield Arc

Super Member

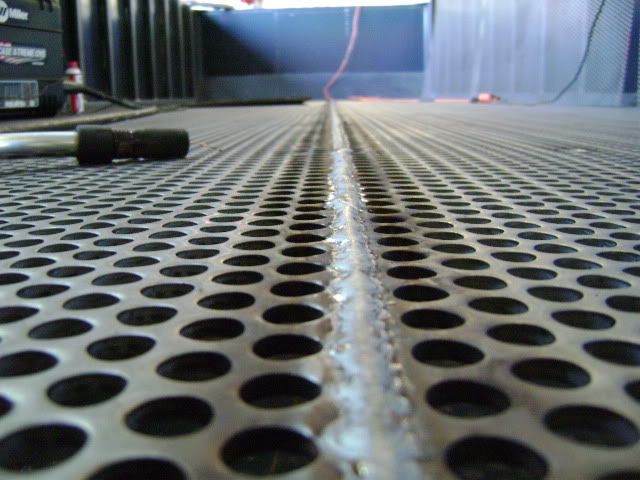

Here are some pictures of open root pipe Tig welding I did this morning. These are far from the perfect "Wedding Band" that everybody shoots for. Most likely these would not pass a visual inspection, unless the inspector was going to cut a lot of slack to an old blind structural hand . They are just to inconsistent!

. They are just to inconsistent!

2 1/2 inch sch 80 pipe, 37 1/2 degree bevel, knife edge, 3/32 inch gap, 1/8 inch filler. Welded in the 5-G position. For anybody that doesn't understand what they're looking at, this is the inside of the pipe, that was welded from the outside. I've never got a straight answer on how much reenforcement is allowed, maybe Gary can give his opinion?

The last picture is a 6-G Tig weld I did a long time ago, it is more consistent. 6-G Tig welding can be a real PITA, because you have to weld with both hands!

2 1/2 inch sch 80 pipe, 37 1/2 degree bevel, knife edge, 3/32 inch gap, 1/8 inch filler. Welded in the 5-G position. For anybody that doesn't understand what they're looking at, this is the inside of the pipe, that was welded from the outside. I've never got a straight answer on how much reenforcement is allowed, maybe Gary can give his opinion?

The last picture is a 6-G Tig weld I did a long time ago, it is more consistent. 6-G Tig welding can be a real PITA, because you have to weld with both hands!