ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,727

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

I love your tenacity and diligence in solving this problem!!! Great work and great reporting. Pictures and videos tell it all.

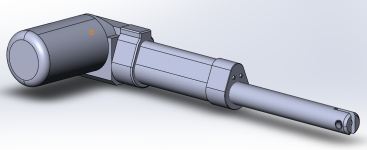

My concerns are protection for the electrical circuit of the actuator.

For example, you hook to your bucket, pick it up and actuate the closer, for some unknown reason the pins aren't lined up. What protects the electrical actuator from burning itself up trying to move an immoveable object?

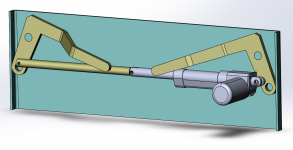

Secondly, you really need to address the length issue before you start using it. Last thing you want is to work your SSQA with the pins only partially latched. Bad results can happen.

As for your estimated hydraulic version costs. I think you are very high.

First you don't want a large cylinder. Maybe 1.25" or at most 1.5". This limits it's ability to tear itself up if something goes wrong during the latch process. Bobcat's system uses a very small cylinder with no relief valve protection.

Second if you already have 3rd function on the FEL all that's needed is an electrical activated diverter valve. Mount it right beside the small cylinder. To latch/unlatch the pins an electrical switch is activated from the tractor seat and the 3rd function valve is used to provide hydraulic pressure.

I'm not saying this is going to be dirt cheap. But if 3rd function exists it could be done very reasonably and would have tractor lifetime durability and longevity.

If you don't currently have 3rd function the cost just went up.

Regardless of my statements, I again applaud your efforts and thank you for honestly and realistically reporting your results.

My concerns are protection for the electrical circuit of the actuator.

For example, you hook to your bucket, pick it up and actuate the closer, for some unknown reason the pins aren't lined up. What protects the electrical actuator from burning itself up trying to move an immoveable object?

Secondly, you really need to address the length issue before you start using it. Last thing you want is to work your SSQA with the pins only partially latched. Bad results can happen.

As for your estimated hydraulic version costs. I think you are very high.

First you don't want a large cylinder. Maybe 1.25" or at most 1.5". This limits it's ability to tear itself up if something goes wrong during the latch process. Bobcat's system uses a very small cylinder with no relief valve protection.

Second if you already have 3rd function on the FEL all that's needed is an electrical activated diverter valve. Mount it right beside the small cylinder. To latch/unlatch the pins an electrical switch is activated from the tractor seat and the 3rd function valve is used to provide hydraulic pressure.

I'm not saying this is going to be dirt cheap. But if 3rd function exists it could be done very reasonably and would have tractor lifetime durability and longevity.

If you don't currently have 3rd function the cost just went up.

Regardless of my statements, I again applaud your efforts and thank you for honestly and realistically reporting your results.