boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,829

- Location

- Trivoli, IL

- Tractor

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

*waves a white flag* it finally clicked in me mind.

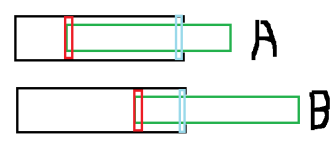

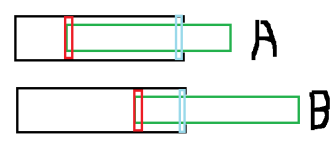

when i started to draw, and just about to open excel sheet to rough calc volume... for total hyd oil volume in A and B diagrams.

B = more hyd oil in the cylinder vs A diagram, that has less total volume of hyd oil in it.

thanks for keeping at me. was in the old fart mood, stuck in me ways and not about to budge.

when i started to draw, and just about to open excel sheet to rough calc volume... for total hyd oil volume in A and B diagrams.

B = more hyd oil in the cylinder vs A diagram, that has less total volume of hyd oil in it.

thanks for keeping at me. was in the old fart mood, stuck in me ways and not about to budge.