jim_wilson

Veteran Member

- Joined

- Jun 13, 2004

- Messages

- 1,794

- Location

- Northeast MA

- Tractor

- Kubota B3200 w/ BH77 & 12", 18" & 24" buckets, Kubota B50 SSQA w/ 54" & 60" buckets, LandPride FDR1660, Artillian Fork frame, Extreme 3pt rake, Concrete Mixer, MyTractorTools grapple adapter

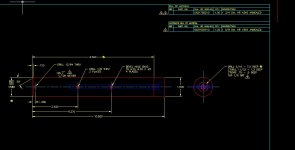

I'd like to make some lubricatable pivot pins for the thumb on my Kubota BH77 backhoe. The factory supplied pivot pins do not have grease fittings and after the hoe sat for a number of months - I ran into a problem because one of the pins was so dry the thumb was hanging up.

I've also got an idea on how to make a "better" pin - which distributes the grease more evenly - but I'm not sure exactly what type of steel would be best suited to making a replacement pin.

Anybody have any insight into this?

Thanks!

I've also got an idea on how to make a "better" pin - which distributes the grease more evenly - but I'm not sure exactly what type of steel would be best suited to making a replacement pin.

Anybody have any insight into this?

Thanks!