flusher

Super Member

- Joined

- Jun 4, 2005

- Messages

- 7,572

- Location

- Sacramento

- Tractor

- Getting old. Sold the ranch. Sold the tractors. Moved back to the city.

I'm getting ready to change all the fluids in the 1966 MF-135 diesel that I'm fixing up.

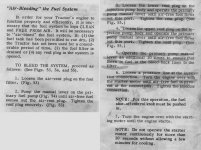

Changing the fuel filters requires bleeding the air from the fuel lines.

That's an easy job on my 2005 Kubota B7510HST--just crank the starter.

Question: is bleeding the lines a slam dunk or a big headache on the MF-135?

Any advice and/or horror stories?

Changing the fuel filters requires bleeding the air from the fuel lines.

That's an easy job on my 2005 Kubota B7510HST--just crank the starter.

Question: is bleeding the lines a slam dunk or a big headache on the MF-135?

Any advice and/or horror stories?