Jnasystems

Silver Member

- Joined

- Nov 12, 2010

- Messages

- 125

- Location

- Waukesha Co, WI

- Tractor

- 1986 Ford/NH 1520, 1950 Allis Chalmers WD, 2001 NH EC35 (track hoe)

Hello all,

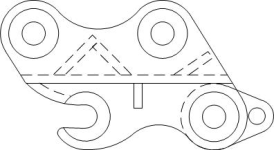

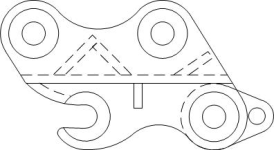

I am thinking about building a quick hitch for my NH EC35 and have some questions about design and machining. First the design, the thought is to create a hook on the front and just pin the back, will this be strong enough to handle the stress? It will be all half inch steel and the tubes will have 5/8" walls. Here is my design:

The next question is how to machine the tubes. I can't find the right size exactly, but I do have a lathe that should be fine for the job. I found new stock that will need 1/8" removed from the inside diameter for $65 and solid 3" bar for $12. Would it make sense to bore the 1-5/8" hole for the pins? Or would that just take forever? Here is the lathe I have - http://www.grizzly.com/products/12-x-39-Large-Combo-Lathe-Mill/G4791.

Thanks,

Joe

I am thinking about building a quick hitch for my NH EC35 and have some questions about design and machining. First the design, the thought is to create a hook on the front and just pin the back, will this be strong enough to handle the stress? It will be all half inch steel and the tubes will have 5/8" walls. Here is my design:

The next question is how to machine the tubes. I can't find the right size exactly, but I do have a lathe that should be fine for the job. I found new stock that will need 1/8" removed from the inside diameter for $65 and solid 3" bar for $12. Would it make sense to bore the 1-5/8" hole for the pins? Or would that just take forever? Here is the lathe I have - http://www.grizzly.com/products/12-x-39-Large-Combo-Lathe-Mill/G4791.

Thanks,

Joe