3RRL

Super Member

- Joined

- Oct 20, 2005

- Messages

- 6,931

- Tractor

- 55HP 4WD KAMA 554 and 4 x 4 Jinma 284

Thanks guys, you guys crack me up.

Since deviating from it's original dedicated use, any ideas or suggestions would very helpful for it's multi-purpose use.

I have to keep within certain guide lines for the mounting system to the other implements since the basic unit is all welded up already. But there is no reason I couldn't change it it a little to make it better or more universal to mount.

What other implements could use I the wheels on?

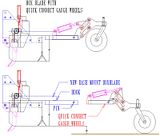

Box Blade

Landscape Rake

Rear Blade

Many of you have stuff I don't, so what else.

How about any more uses for it thinking out of the box. How about a wheeled harrow of some sort?

And maybe not necessarily tractor implements?

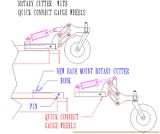

For example, how about like a pallet jack? I realize would need some other stuff to make that happen, but these wheels that raise up like this, what else would be a use for Quick Attach Wheels that raise up? I could make a separate power source (hydraulic mule) and front wheels that slip under. Not only that, but the big rotary cutter wheels also pin on and off, so I could replace them with smaller casters etc.

What I'll do is finish it up and paint it. I'll drill the holes for the universal mounting pins first and then post some photos of it. That might stimulate some more ideas such as where the best place to mount it on the other implements would be (height and aft) and what else it could be used for. This could be a big deal.

Keep the ideas coming guys. I like the kick stand and receiver idea a lot. I might make the rails or receivers to show what the base mount will be like, since it needs to fit the wheel frame. But I might not do that yet in case someone comes up with another idea for the base.

Since deviating from it's original dedicated use, any ideas or suggestions would very helpful for it's multi-purpose use.

I have to keep within certain guide lines for the mounting system to the other implements since the basic unit is all welded up already. But there is no reason I couldn't change it it a little to make it better or more universal to mount.

What other implements could use I the wheels on?

Box Blade

Landscape Rake

Rear Blade

Many of you have stuff I don't, so what else.

How about any more uses for it thinking out of the box. How about a wheeled harrow of some sort?

And maybe not necessarily tractor implements?

For example, how about like a pallet jack? I realize would need some other stuff to make that happen, but these wheels that raise up like this, what else would be a use for Quick Attach Wheels that raise up? I could make a separate power source (hydraulic mule) and front wheels that slip under. Not only that, but the big rotary cutter wheels also pin on and off, so I could replace them with smaller casters etc.

What I'll do is finish it up and paint it. I'll drill the holes for the universal mounting pins first and then post some photos of it. That might stimulate some more ideas such as where the best place to mount it on the other implements would be (height and aft) and what else it could be used for. This could be a big deal.

Keep the ideas coming guys. I like the kick stand and receiver idea a lot. I might make the rails or receivers to show what the base mount will be like, since it needs to fit the wheel frame. But I might not do that yet in case someone comes up with another idea for the base.