tommu56

Elite Member

Rob

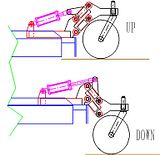

The farmer that I lived next door to went from a single rear wheel mower to a dual wheel one (all auction equipment of course) he had a top link on rear wheels to adjust them it worked fine it pulled on draw bar not on 3 point so it stayed parallel to ground.

It never scalped any thing when I used it, a big plus.

The only minus that he said he missed not being able to lower it on something to shred it like his 3 point could.

When get a cutter I will seriously consider spending the extra for the 2 wheel one

tom

The farmer that I lived next door to went from a single rear wheel mower to a dual wheel one (all auction equipment of course) he had a top link on rear wheels to adjust them it worked fine it pulled on draw bar not on 3 point so it stayed parallel to ground.

It never scalped any thing when I used it, a big plus.

The only minus that he said he missed not being able to lower it on something to shred it like his 3 point could.

When get a cutter I will seriously consider spending the extra for the 2 wheel one

tom