Spencer

Veteran Member

- Joined

- Jan 2, 2002

- Messages

- 1,267

- Location

- Western Michigan

- Tractor

- NH TC33D w/R4 Tires, Rear Remote, Hydraulic Toplink, 2 Auxiliary Work Lights, 7308 Loader w/Kasco Uni-Hitch (Quick Tach)

Hi everyone, unfortunately I have not had the time to read or contribute to TBN in the last few months. I still don't really have the time, but I wanted to share my latest project with you.

I don't have loaded tires on my TC33D and the rear end often gets light while I am doing loader work. I did put on two sets of NH rear wheel weights shortly after I got my tractor, but I still need more weight back there. I often have my 6 foot rear blade on the back of the tractor to help add some weight, but that makes maneuvering a little tricky at times and it isn't really as heavy of a counterweight as I would like. My 60" rotary cutter does the best job as a counterweight, but that really makes maneuvering a challenge through my woods.

I went shopping for a ballast box last year and quickly decided against them. They are pricey for what you get and I knew if I had the time I could weld one up for a fraction of the cost. I have seen many concrete ballast projects here on TBN and that really seems to be the best way to go. Many of you have added a standard trailer hitch or 2" receiver to your concrete ballast projects and I decided to borrow that idea. Wroughtn_Harv uses those 2" receivers all over the place to mount vises and benders, etc. and I decided to borrow that idea as well.

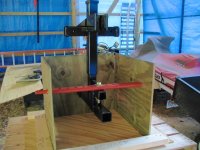

This first picture shows most of the metal that I used in this project. By the way, that is the correct date in the photo. I started welding up this project back in March when I had a little time to spare.

I don't have loaded tires on my TC33D and the rear end often gets light while I am doing loader work. I did put on two sets of NH rear wheel weights shortly after I got my tractor, but I still need more weight back there. I often have my 6 foot rear blade on the back of the tractor to help add some weight, but that makes maneuvering a little tricky at times and it isn't really as heavy of a counterweight as I would like. My 60" rotary cutter does the best job as a counterweight, but that really makes maneuvering a challenge through my woods.

I went shopping for a ballast box last year and quickly decided against them. They are pricey for what you get and I knew if I had the time I could weld one up for a fraction of the cost. I have seen many concrete ballast projects here on TBN and that really seems to be the best way to go. Many of you have added a standard trailer hitch or 2" receiver to your concrete ballast projects and I decided to borrow that idea. Wroughtn_Harv uses those 2" receivers all over the place to mount vises and benders, etc. and I decided to borrow that idea as well.

This first picture shows most of the metal that I used in this project. By the way, that is the correct date in the photo. I started welding up this project back in March when I had a little time to spare.