Nice project, and finish work. Can't see any defects from here, and once you've graded and asphalted, etc. the building perimeter only you will know what isn't perfect. Considering the wind factor and other site specific issues everything turned out well.Who was/is the 'safety dog'; some sort of inspector?

Good on renting a man lift. I didn't like seeing the man on the top of the 10 rung folding ladder, even with the 2 helpers holding it. I know contractors who've worked for me who have died from falls, and one never wants to see that type of thing happen.

One thought on going bigger than the initial building. You could expand by setting columns on concrete sono-tube based piers, or the type that are pyramid shaped preformed post bases, then construct your addition, walls, roof etc., later adding a slab inside over a compacted stone base. In the meantime you would have extra space to use, and could pour your floor as it became affordable; or never if you could use the stone base for certain things like I did with my boat, ATVs, lawnmowers, ladders, etc.

And you could add solar panels to your roof to cut your AC/electric costs. I just did 30 panels and a German manufactured battery storage system, (16kW), which gets primary use, and keeps me off the grid. So my power company gives me a credit of 5.3 cents over what I pay per/KWh, AND I still get to use the power generated by the PV panels! So the solar credits can be used for any $ owed during the winter months, (read snow covering the panels, etc.), and the rest of the time the batteries store the power generated by the PV cells, and they get drawn down with use. AND I got a 30% tax credit from the project's install cost, including all electrical wiring to tie the PV and batteries into my existing house, barn, 2 sheds, etc. to use against any gains that I might have to otherwise pay uncle sammy. With the amount of sunlight you have down there you'd be golden.

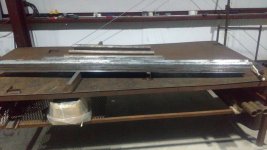

This is 8 box traps and 4 corral traps all cut and ready to start welding this morning and a welding table with all the rust brushed off.

This is 8 box traps and 4 corral traps all cut and ready to start welding this morning and a welding table with all the rust brushed off.