Last weekend we started fitting the electric solenoid valve mounting bracket to Loretta's Jinma. Loretta left the ordering or materials up to me since I've had experience doing all this before on my Kama 554. The valve is a true third function double action solenoid valve so the grapples can be operated

simultaneously with the other FEL functions. That is, while curling/dumping and raising/lowering the bucket all at the same time.

It is not a diverter valve where you lose (usually) the curl to operate the grapple.

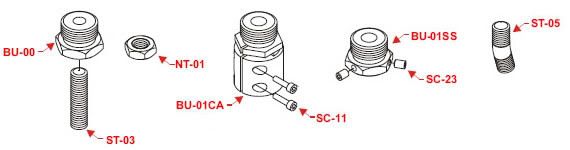

We purchased the components from Surplus Center.

They are for an OPEN center system like most of our tractors. For those of you interested in a DIY valve installation like Loretta's, these are the components you need, or least the ones that I used. Of course there are several others to choose from, but these are pretty reasonable.

Click on the link for details.

The valve is an open center

EATON-VICKERS DG4V-3 12 VDC 10 GPM OC DA SOLENOID VALVE

The subplate is

DO3 1 STATION SUBPLATE which can be used for either open or closed center valves.

The electrical connectors are

HIRSCHMANN CONNECTOR FOR DG4V3 SOLENOID VALVE and you need 2 of these for installation of wires to solenoid coil and up to the switch on the joystick handle.

Click the pictures to enlarge them.