You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need advice on welding machine purchase

- Thread starter ArtMech

- Start date

- Views: 8422

More options

Who Replied?

/ Need advice on welding machine purchase

#31

ArtMech

Platinum Member

- Joined

- Oct 5, 2010

- Messages

- 952

- Location

- Lithuania, EU

- Tractor

- Present: 2003 Kubota M9000 DTF; 2001 Kubota B72. Sold: 1985 Kubota L2202

Back stepping your welds, and skipping around a lot. And making welds on opposite sides of each other are a big help in countering distortion.

Thank you, Shield Arc, I understand your advise. And indeed I'll take it into account for the future.

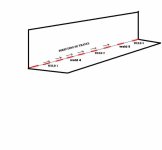

But please take a look at another picture attached. In fact the bucket edge should be welded from opposite (bottom) side first and, after turning it over, - from another side (inside). Distortion may occur within bottom side welding. As you may see, maybe the welding of stiffening strips 15x40 mm (yellow arrows) from underneath could do that "bad job" of edge distortion. Continuous lines (red arrows) are of welding together of 4 mm sheet and 20 mm thickness edge. It is welded with MIG by another guy, not by me with my MMA.

View attachment bucket welding 1.pdf

Last edited:

Shield Arc

Super Member

If you follow my method, you'll have a fighting chance. But sometimes things will warp no matter what you do while welding. That's when you heat shrink. Or use a hydraulic jack, and a strong back, to force it into shape.