woodlandfarms

Super Member

- Joined

- Jul 31, 2006

- Messages

- 6,151

- Location

- Los Angeles / SW Washington

- Tractor

- PowerTrac 1850, Kubota RTV x900

So we went on city water a few years ago and were required to abandon our old well. But I made sure I saved the pump (it was fairly new). I now have a use for it (pumping water out of a pond) but I am unsure of wiring. My hope is that I do not need all the complicated control panels as I have them, but they are now buried behind shelving.

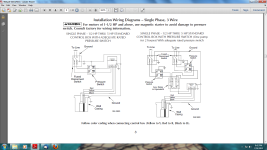

The pump is a gould 4" submersible model # 10LS05412. Wire colors are Red Black Green and Yellow. I intend to run this off my 5K generator which as 220. But now I am stumped. Green appears to be ground as it is thinner (and the color would be correct) but I am unsure of the other colors.

Anyone have any advice they can impart. I have struck out on the net other than tech specs that are over my head.

The pump is a gould 4" submersible model # 10LS05412. Wire colors are Red Black Green and Yellow. I intend to run this off my 5K generator which as 220. But now I am stumped. Green appears to be ground as it is thinner (and the color would be correct) but I am unsure of the other colors.

Anyone have any advice they can impart. I have struck out on the net other than tech specs that are over my head.