BHD

Veteran Member

a few years ago, I wrote and asked about bifold doors for the shop, I have a 13 foot x 13 foot opening,

not that large, but we do have wind, and currently I do not want to spend money on a commercial door, the simple is I do not have that much to invest in a door at this time, but need a door,

considering a bifold desigin, and solid door plan,

on the bifold, this idea with the extended hinge, so there is less loss of head room,

https://www.youtube.com/watch?v=XJwIdLt1QMg

https://www.youtube.com/watch?v=EIqfLuASe_c

and this Idea caught my attention,

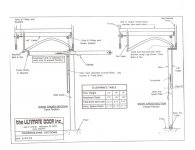

ultimate

picture from flyer below, which uses a track to guide the door up and in to the building, (some one with experience with on said on a large hanger door, they did not work that good, jerky and not smooth),

over the week end I was thinking about this and the thought was to use a arm that pivots to guide the door on top,

not the best picture but a picture of the building I am wanting to put it in,

considering a walk in door in the big door, as well,

not that large, but we do have wind, and currently I do not want to spend money on a commercial door, the simple is I do not have that much to invest in a door at this time, but need a door,

considering a bifold desigin, and solid door plan,

on the bifold, this idea with the extended hinge, so there is less loss of head room,

https://www.youtube.com/watch?v=XJwIdLt1QMg

https://www.youtube.com/watch?v=EIqfLuASe_c

and this Idea caught my attention,

ultimate

picture from flyer below, which uses a track to guide the door up and in to the building, (some one with experience with on said on a large hanger door, they did not work that good, jerky and not smooth),

over the week end I was thinking about this and the thought was to use a arm that pivots to guide the door on top,

not the best picture but a picture of the building I am wanting to put it in,

considering a walk in door in the big door, as well,