PapaPerk

Veteran Member

- Joined

- Jun 12, 2004

- Messages

- 2,403

- Location

- USA

- Tractor

- Kubota L3830, Ford Golden Jubilee, 1939 Sears Economy, Polaris Ranger 400, Honda Foreman 450 ES, 2004 Dodge Diesel 3500

Reading this long discussion on how to in the mind get farm equipment to work in real situations.

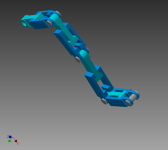

Was reminded of a inventor named Laturno probally mis-spelled Built elec. motors in the wheels and small generator on frame of what ever the machine was to do.

A loader commonlly called the bouncing betty had 5 buttons on dash for movement forward, left, right ,rearward. the fuel tanks were in the frame .

All before the modern electronic controllers could work in any weather conditions and didn't need a table smooth surface to get around.

Study history of international tractors company. every time the engineers built a piece of farm equipment that the farmers liked the bean counters turned it down as to costly.

With all the electronics . hydrolic motors hoses and parafanalla in your design should something like a operator that has no idea what he is doing connect the wrong hose to piece of equipment. insted of folding turning or doing as designed it curls all into a mass of junk. Who is to repair all of this when a part is bent due to trying to run into a power pole in field .or miss alignment in corn crop and it takes out the corn row instead of doing what was thought it is doing.

Again reading all most all of this forum just what are you trying to build.

Farmers buy equipment to get the job done if it doesn't it is sidelined for something that does.

Example is dairy men buying these 1/4 millon dollor automatic milkers and the electronics get hit by lightening.

Do you ask the cow to be patient while waiting for the repairman to arrive. Or harvesting the rice crop and the weather has turned the field into a 4 inch deep pond . have to use a dozer to drag the combine across the field. fill the trailers to take to the storage area and the tractor (driver trying to get his head phones adjusted) runs the tractor into drainage ditch. turning it over.

Can all the planning over come just the changing weather conditions.

Sometimes I cannot sleep also.

ken

I think it's spelled LeTourneau. He was an equipment genius.

R. G. LeTourneau - Wikipedia, the free encyclopedia