YA! finally got into doctor today, and get some injections, to deal with some muscle nerve issues. hopefully my mind will be speeding down the field once again at full throttle. vs trying to figure out what 2 plus 2 equals.

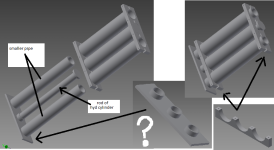

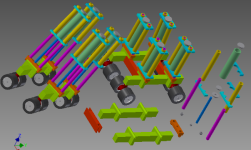

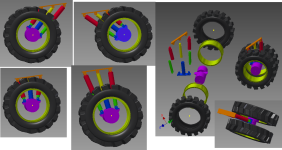

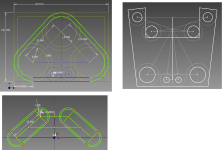

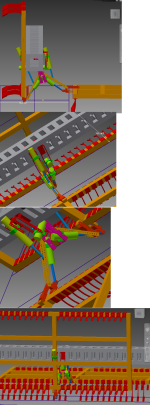

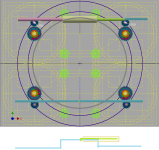

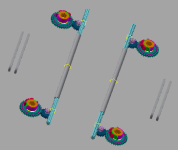

back to the transport wheels.... at one time i thought i would be able to make it so there would be 4 wheels (2 lefts, 2 rights) would have there own set of raising lowering cylinders, and own cylinder for 360 joint to rotate it. but space is simply not there, without adding an extra 8 to 12 inches. and if i add the extra space, and transport wheels sink up to the axle other parts would be dragging and digging in as well, and just be one ugly stuck mess trying to get the SSTT (sideways snake train tractor) out of the mud.

but now it is look like....

2 front left

2 from right

2 rear left

2 rear right

total of 8 tires. will have 4 hyd cylinders to raise and lower them to the ground. and then i am not sure if i am going to stick with a single hyd cylinder or go with 2 hyd cylinders to rotate the 360 joint.

i have room to enlarge the reduction gears. and i might be able to either run a shaft between left side 360 joints and another shaft on right side 360 joints. problem is... keeping everything as low profile as possible.

WAIT a min....

that might work better, a hyd cylinder on left side 360 and a hyd cylinder on right side 360 joints. and keep all the ugly shafts from going from left to right side and vice vs....

hhmmsss THE PROBLEM.... needing adjust wheels for row / crop. doings. GGGRRRR. i guess go back at it and see what i can come with vs, shorting the idea out, vs seeing if it is even possibly by rough set of numbers.

========================

========================

=========================

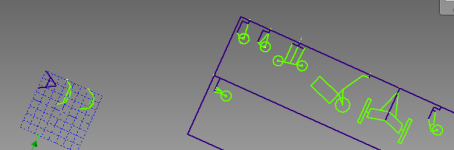

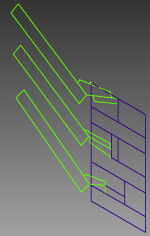

on a different note, been going over...

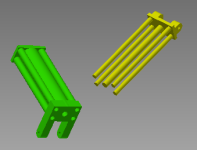

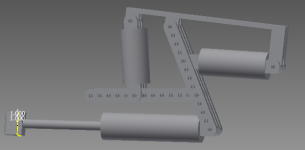

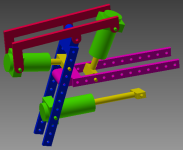

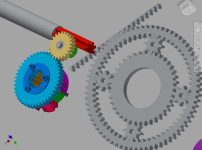

hyd pumps. a good portion of the yesterday, was re-inventing the wheel. and trying generic stuff out in autodesk inventor, ya it may seem pretty pointless, but it was a learning experence, and helped me clarify, what would and would not work. and portion of today, was re-looking back at video's on youtube.

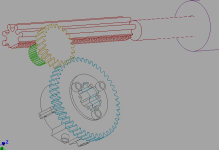

i am down to axial and radial type of hyd motors.

the one big issue has been, using up space, as in the replacing the rim of a tire with a hyd motor. looking over on

Please wait while we redirect... website. all the hyd motors are foot ball size. give or take a few inches in any direction.

also the piston sizes or rather cubic inch of displacement and GPM and RPM, and PSI

the RPM's for transport wheels are a bigger issue compared to field only mode large 4 foot diameter AG/R1 tires, and tracks for in field mode. transport tires need the low RPM's while in field mode, then high RPM's when in transport mode going 25 to 40 MPH down the road. and honestly been looking at 65MPH down the road. why not at this point. no were near a point of being able to narrow things down.

gearing is an issue.

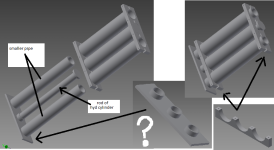

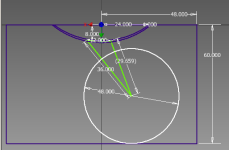

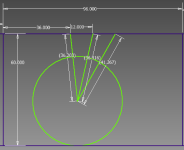

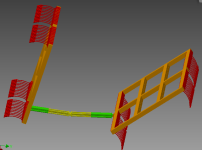

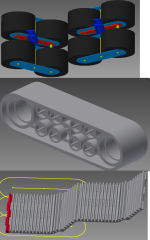

---thought about instead of gearing, put in 2 circles of pistons in a axial hyd pump, the smaller ring, fewer piston circle = higher RPMs or MPH, and then the larger ring with more pistons, = slower speeds and more torque. and then dropping a 1 to 3 speed transmission / gear setup.

---for radial hyd motors putting in 2 rows one with larger pistons and another row beside it with smaller pistons. and same as above, smaller pistons = for higher RPMs / MPH, and larger pistons for slower speeds and more torque.

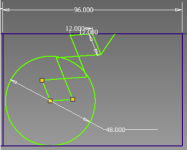

----i have thought about setting up 2 rows of pistons of same size for both axial or radial hyd motors, and instead of running all the pistons in parallel all the time which would give a lower RPM and high torque, i thought about running every other one or 2 or 3 in series, and en essence change gears for higher RPM's other words, i would be changing a 4" diameter bore hyd cylinder 3" inches long. to a 1" diameter bore hyd cylinder 24 inches long. ((how ever that math works out, to lazy to open up spread sheet and do the math for this example)) by simply changing the pattern of were hyd flows in/out of each piston.

----i have also thought about just beefing up the metal, of everything. so i can just push more GPM of hyd oil through a hyd motor. to get the RPM's that would be wanted. that in itself, i don't know about this idea, due to higher GPM that get pushed through the hyd motor, the more friction loss that is created. and efficiency begins going down, along with more heat that gets produced. more GPM = larger size hyd hoses and pipes. larger hoses = smaller bend radius of hoses before causing problems with the hoses, and there will be enough hoses, that bend radius could be a big problem. and then with heat, = more hyd oil cooling that would be needed and efficiency just keeps going down across the entire SSTT. i could raise hyd pressure from 3000PSI up to say 5000PSI, but for now trying stay with 3000PSI hyd oil pressure. larger diameter hyd hoses cost $$$ more. not talking 1/2" or 3/4" but more likely 1" to 2" in order to keep friction loss down to an acceptable level.

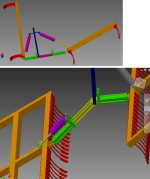

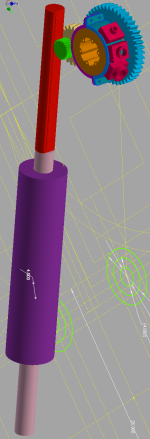

=================

actual regular gears like in a transmission. i have been thinking about them. from planetary to spur gears. and different arrangements. and at moment, i keep jumping away from gears. good portion is, because, i do know know / comprehend, the math that is needed to be known. for gears. and to keep gears from stripping teeth and like. but other is, physical space that is there, to place gears. i need room for a hyd motor, brake, gearing, and have room to place in each rim of 2 wheels, and then a short 4 to 8 inch width between the 2 wheels. plus need to route some wires for sensors and hyd oil itself. plus an air line for brakes. possibly an another air line, to supply air pressure to shift between gears. then gear oil or hyd oil, to everything. if hyd oil. do i run another small little hyd pump and pump fluid back and forth between each axle or install or other.... those higher end MPHs are going to be creating some heat in them transport tires, when sstt is in transport mode going down the road.

that last paragraph in itself is overwhelming me at moment.

===========================

===========================

ya and i thought it would be simple, *chuckles with a grin* off to make some plates for hyd motors, to see if i can run all pistons parallel, and/or every other 1,2,3,4,5,6 in series.