OP

boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,829

- Location

- Trivoli, IL

- Tractor

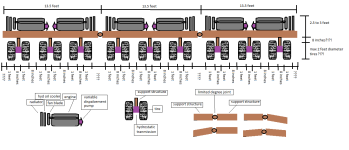

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

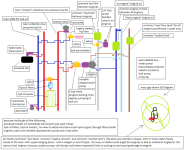

forgot to add, "common coolant tank" antifreeze/water mix, and main lines to goto each engine. ((to allow engine to be flipped upside down and any which way. and not have water pumps suck air))

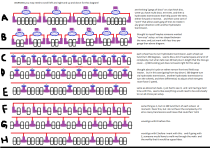

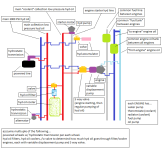

need to re-look at schematics for hydrostatic transmissions and variable displacement pumps. to figure out were load sensors, torque sensors, pressure sensors, etc... could be placed. or if some extra main lines need to be added to handle certain sensors.

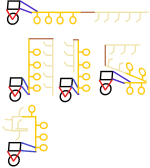

currently trying to figure out a way, for "quick disconnect" for engines. so they could be quickly pulled, and replaced with other engine if need be. while broken down engine gets repaired. perhaps as an optional kit?

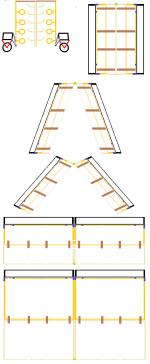

still have not figured out how implements would attach, and how things would fold / unfold. so no hyd cylinders in the mix yet. but kinda thinking some "hyd accumulators" might be tied in between "main 3000PSI hyd line" that currently feed hydrostatic transmissions on the wheels. and then another main line that feeds hyd cylinders. that fold/unfold things. to allow for quicker response time. though might upgrade 5 way valve on each engine to a 6 way valve. hhmmsss....

================

went with hydrostatic transmission to an alternator. if engines are all diesel. no need to power spark plugs, just leaving just a bunch of electronics to power. most of which, i would like to think would be low amp units. exception for lighting. figured hydrostatic transmission would allow for differences in variable displacement pump/s on engines. and be able to turn alternator at a given RPM as needed.

went with a "hyd accumulator" on "main starter hyd line" thinking some engines might be a tad harder to start. and hyd accumulator plus starter motor with hyd pump. might be able to help over come those hard to start engines.

===============

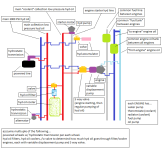

cold start options for engines... hmmmsss. around here it is mostly just corn and beans that are planted. and no real need for a "field" tractor to be used in winter... or rather when temps are near freezing. i suppose though only one engine would need a cold start option. and once it gets started, it could help start the other engines. i suppose a simple "glow plug" on intake manifold on each engine could be easily done. just a wire.

eeewwww..... grounding and multi engines.... never thought about possibly electrical interference between everything. *rubs chin* that should not be a problem. exception if some sort of wireless connection is used. hhmmss... but man, just one wire or switch that went bad, and allowed things to ground out... that would wreck havoc on entire system possibly. would a feed back sensor possibly allow for a switch / electronic valve is working correctly. and if not kill the switch / valve. and give an alarm sound?

need to re-look at schematics for hydrostatic transmissions and variable displacement pumps. to figure out were load sensors, torque sensors, pressure sensors, etc... could be placed. or if some extra main lines need to be added to handle certain sensors.

currently trying to figure out a way, for "quick disconnect" for engines. so they could be quickly pulled, and replaced with other engine if need be. while broken down engine gets repaired. perhaps as an optional kit?

still have not figured out how implements would attach, and how things would fold / unfold. so no hyd cylinders in the mix yet. but kinda thinking some "hyd accumulators" might be tied in between "main 3000PSI hyd line" that currently feed hydrostatic transmissions on the wheels. and then another main line that feeds hyd cylinders. that fold/unfold things. to allow for quicker response time. though might upgrade 5 way valve on each engine to a 6 way valve. hhmmsss....

================

went with hydrostatic transmission to an alternator. if engines are all diesel. no need to power spark plugs, just leaving just a bunch of electronics to power. most of which, i would like to think would be low amp units. exception for lighting. figured hydrostatic transmission would allow for differences in variable displacement pump/s on engines. and be able to turn alternator at a given RPM as needed.

went with a "hyd accumulator" on "main starter hyd line" thinking some engines might be a tad harder to start. and hyd accumulator plus starter motor with hyd pump. might be able to help over come those hard to start engines.

===============

cold start options for engines... hmmmsss. around here it is mostly just corn and beans that are planted. and no real need for a "field" tractor to be used in winter... or rather when temps are near freezing. i suppose though only one engine would need a cold start option. and once it gets started, it could help start the other engines. i suppose a simple "glow plug" on intake manifold on each engine could be easily done. just a wire.

eeewwww..... grounding and multi engines.... never thought about possibly electrical interference between everything. *rubs chin* that should not be a problem. exception if some sort of wireless connection is used. hhmmss... but man, just one wire or switch that went bad, and allowed things to ground out... that would wreck havoc on entire system possibly. would a feed back sensor possibly allow for a switch / electronic valve is working correctly. and if not kill the switch / valve. and give an alarm sound?

Last edited: