electrical motors vs hydrostatic transmissions hhmmmsss....

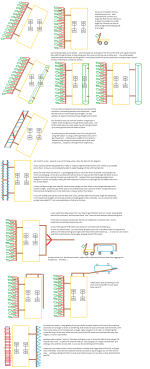

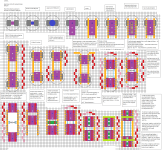

it one of the things that keep coming back to me. is say place 12 hydrostatic transmissions down in the transmission box. and place 3 hydrostatic transmissions per wheel set. and as torque is needed one or all 3 per hydrostatic transmission would turn on and start going.

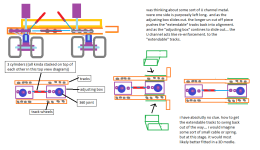

been looking at various swash plates setups...

HOW IT WORKS with double pistons. and swash plate i am also liking. 3 cylinders and then a flip of switch and get all 6 cylinders moving and in that get more torque and/or RPMs or combo of both.

tractors really due love torque to get them wheels or tracks to spin across the ground. and to drag implements through the ground. what power would be put to speed in a race car is transferred to torque for tractors...

and been going back and forth between having single larger hydrostatic transmission per wheel sets, or going with multiple hydrostatic transmissions.

i like idea of a double ended piston. for what ever reason. but i am not sure about RPM and a min amount that would be needed to obtain a nice smooth ride vs jerkiness coming from such a thing. i suppose more cylinders per side, and smaller size diameter and length of cylinders. might prove better for a better smoother ride.

========

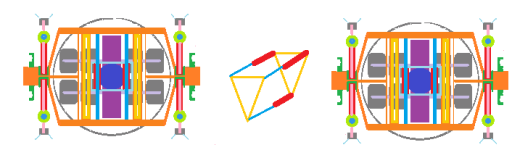

before i forget, if using a 4way valve below 360 joint. to change direction tires rotate with hydrostatic transmissions. the spool for the 4 way valve and lever for hydrostatic transmission. might be hooked up into same connection point. so only a single servo could be used...

========

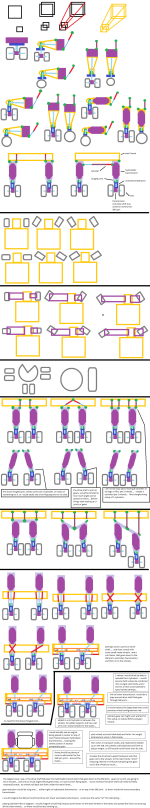

getting back to using larger hydrostatic transmissions to using multi smaller hydrostatic transmissions. i hate friction loss. more friction the more heat that gets created. any time a fluid has to make a sudden quick turn, or go through a small narrow passage, friction gets created. larger hydrostatic transmissions would i guess have larger areas going through the entire unit and in that less heat being created...

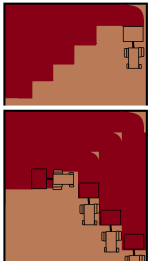

electrical motors. is there a min amount of RPM's that they need to turn. to actually start moving without requiring extra electricity to keep them turning at very low RPM's. i could see a SBT (side train box) tractor have one end stationary and does not move from its spot, as the other end makes a very long 180 degree turn. the wheels near the end that does not move will need to barely move say a 1/16th of an inch a minute, while wheels on the far other end may be moving 5 to 25 MPH. and to keep everything straight across the entire width any were from 20 to 120 feet plus of tractor. those micro adjustments of how much a wheel turns would be needed. and the force / torque to keep the wheels from rolling away. vs going back into a rut, or wheels wanting to roll back down a hill.

with an electrical motor. how do you "stall the motor" so it does not free spin, when no electricity is applied? i know there is some stiffness to electrical motors. but only way i could think they could work on STB tractor would be with combination of brakes. to point that brakes will be slightly applied while wheels get turned with an electrical motor. those brake pads or like would be fried up in no time....

on other hand with hydrostatic transmissions. i would like to think some use of some valves. everything could be achieved. more so with a load sense setup on hydrostatic transmissions. were valves do not open up till system pressure (pressure from pump) meets the pressure on tires plus a predetermined extra PSI.

hhmmsss... i suppose use of clutch plates and brake plates all rolled into one. you might get away with electrical motors. but still the wear and tear they would receive...

a constant starting stopping electrical motors. would most likely put a huge strain on motors i would imagine. along with the electricity that it takes to initially start a motor would put some pretty good surges of power through the system. granted hydrostatic transmissions would also put a strain on things. though i would imagine a hyd accumulator or so could be placed into hyd oil circuit to reduce the spikes / sudden surges. for electrical i would imagine large size capacitors?!? (hope got term correctly been a while) i would imagine these capacitors would take some time to drain themselves of electricity when STB tractor was shut off, and things had to be worked on. requiring some sort of "by pass" around the capacitors... same thing with hyd accumulators, but with hyd accumulators. a quick valve could release all the built up pressure in multi hyd accumulators. vs capacitors if there were multi switches per multi set of capacitors across the entire STB tractor, any switch that went bad, still could put out high electricity out into the tractor...

i just can not see use of generators being placed on STB as primary power. and using electrical motors to drive the wheels. it is not the cost aspect, but the maintenance and repair. that has me. and the safety aspect. of a short circuit and things going quickly wrong. with entire machine. vs hyd oil. ya there may be something that requires a STB tractor to completely be shut down and left in field. but one or a few hyd oil failures would not destroy the rest of the machine or rather multi components of the machine.

well crud, *looks over at the breaker panel in the basement* had mind set of treating electricity like hyd oil. and not thinking about isolation ability of a breaker panel. and more so breakers able to trip at various settings... but still. i know wires get damaged, i know hyd fittings, hoses, etc.. get scratched up, dented, torn apart. and if it does not happen, you have not been in the seat of a tractor long enough.

if ya dealing with 60 to 120 feet plus STB tractor. will you really be able to catch an oil leak? or let alone see it? once you drove a few feet let alone half way across the field when a warning light comes on? and see all the hyd oil spitting out... with electrical, problem would be isolated. and hopefully breaker trips... and would not be dumping gallons upon gallons of hyd oil onto the ground... or have hyd oil drips going all over the place. on other hand if wires get shorted out and breaker does not trip. hhmmsss....

for tractors. there really is no need for "power savings" were electrical motors turn into alternators. and recharge a battery set / capaciters. when in field, with implement on the ground. i would imagine you would want all tires spinning and keeping the same torque placed on all tires. for a more even compaction (thinking less compaction). vs putting more torque on certain wheels and creating more compaction... the only time power savings would actually work would be when STB tractor is in transport mode going down the road and going down a hill. but with all the weight of a STB tractor and to keep things moving... i just do not see a "power savings" as useful.

=================

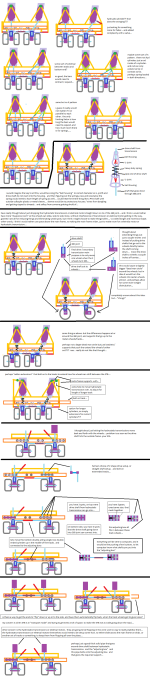

ok a hybrid setup.... mixing electrical motor and hydrostatic transmission. and having one generator and another engine running a hyd pump. seems like a large pain to try to keep electrical motor and hydrostatic transmission. working together and operating at same RPM's even when gearing and like all figured out. i suppose a RPM gauge on hydrostatic transmission shaft. and then RPM sensor on electrical motor shaft. and some sort of dimmer like switch used to adjust electrical motor amps might work. and perhaps doing same thing for hydrostatic transmission with 4 way valve. and adjust how much hyd oil goes to a hydrostatic transmission.

i suppose running a hybrid setup, implements could be mix and matched to what ever suited the implement the best.

=======

side note, why do wires need to go through center of a 360 joint with a special fitting? turn the diameter of the 360 joint into into a special fitting. that would solve problem of getting wires out of a pipe... and resolve some of the bottle neck effect of a 360 joint.

======

i would imagine there is a pretty hefty electrical need for a STB tractor, from all the sensors, switches, servos, and then night time driving, you no longer get away with lights concentrated around a single area. but spread out the entire width of the STB tractor 20 to 120 feet plus... a hybrid setup. might match that doing pretty good. it is either that, or all engines on the STB having an alternator. or installing a generator head, with a clutching between engine and generator head. so small generator could run electrical needs of STB tractor. while primary power is hyd fluid... hhmmsss that is another problem. electronics and generators, and making sure they get good clean power. vs ugly waves of power that could kill electronics in short order...

a larger engine / generator would more likely make it worth while and save cost for putting out good clean power. and then remove need for alternators on all the engines...

perhaps one primary diesel engine with hyd pump and generator head attached to it. then second engine would just be turned on an ran at what ever RPM's that are needed that the primary engine is not able to produce for hyd oil. and for backup. power connectors between sections could be used...

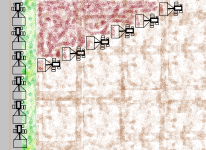

ggrrr i need to break out of a small 20 section design. and start thinking 40, 60, 80, 120, 240, 360 feet plus widths for the STB (side train box) tractor. and include cab and non cab versions of sections. to get a better handle on things...