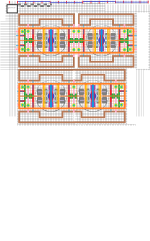

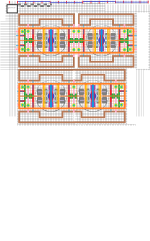

RECAP 3

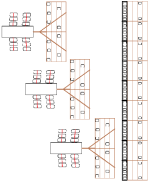

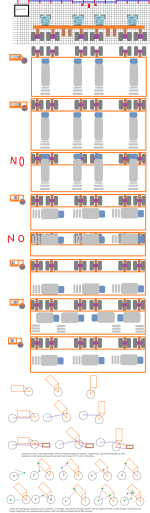

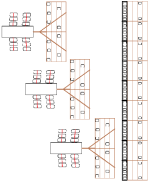

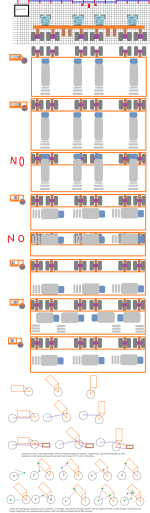

post# 81 = all diagrams from the previous 80 posts.

been jumping all around on different ideas/subjects.

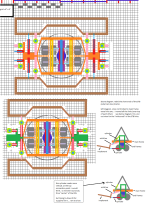

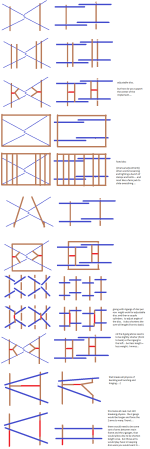

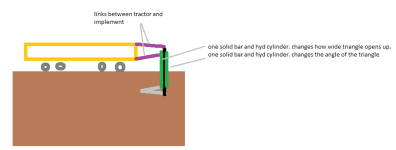

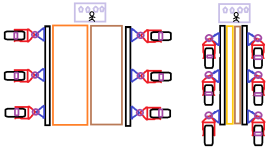

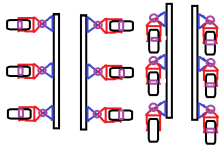

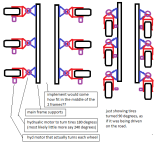

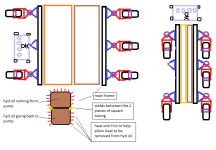

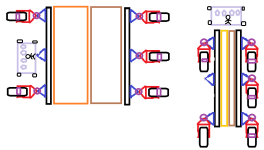

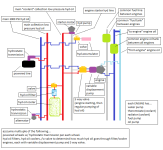

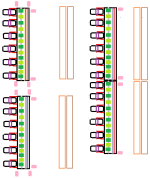

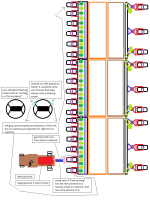

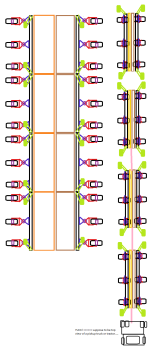

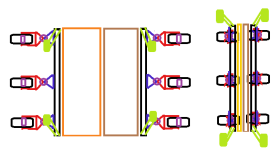

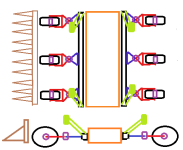

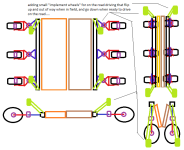

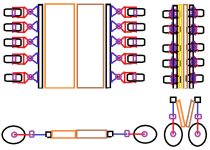

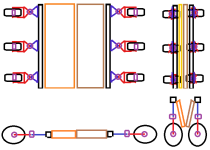

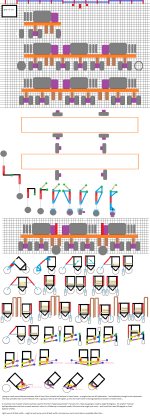

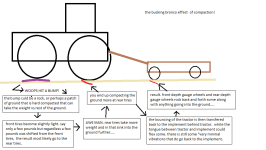

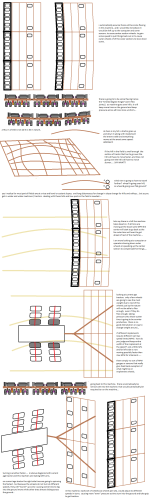

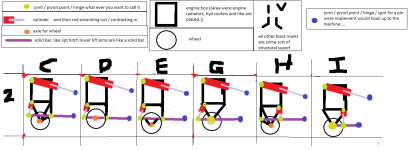

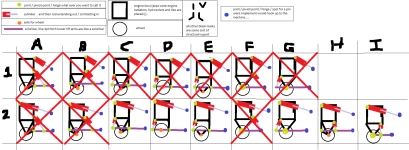

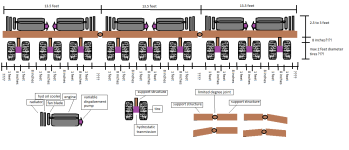

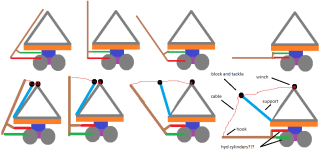

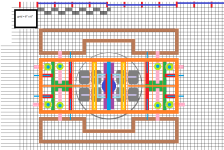

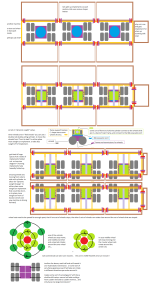

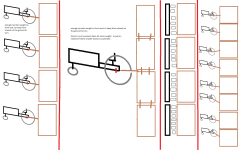

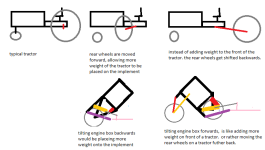

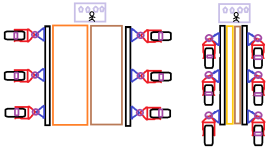

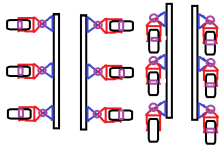

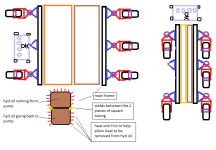

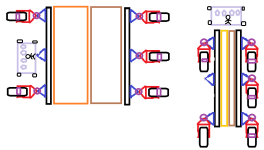

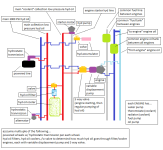

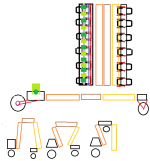

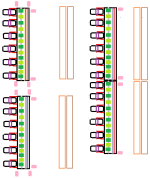

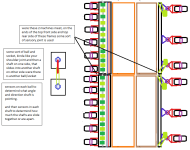

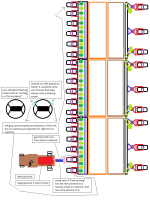

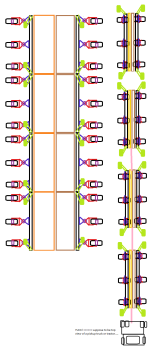

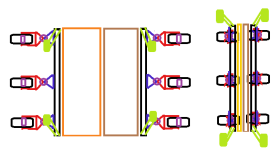

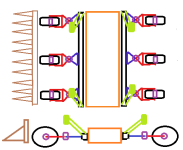

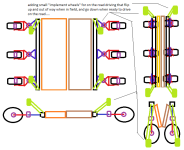

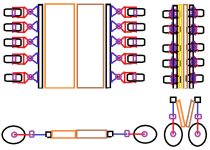

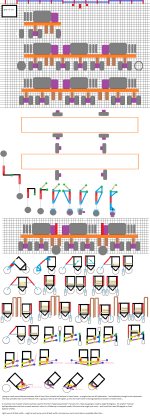

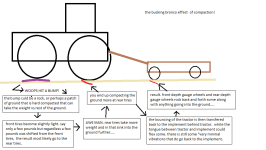

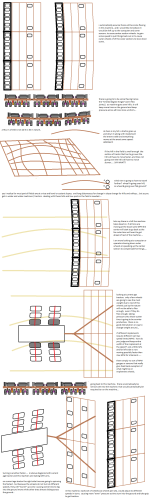

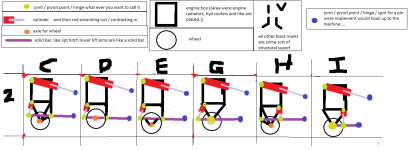

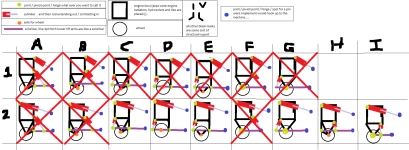

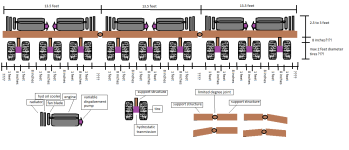

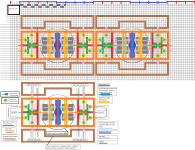

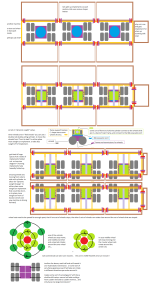

for most part shortened overall width of machine, and redid how the links (3pt hitch like links) connect to the STB (side train box) tractor.

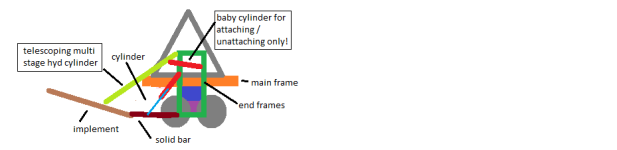

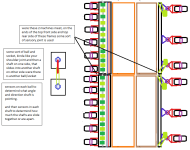

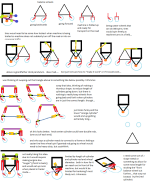

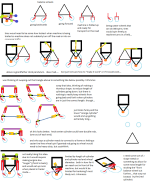

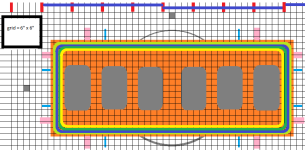

i suppose i should start saying 2point quick hitch connections.

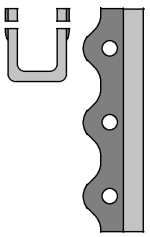

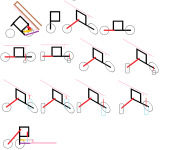

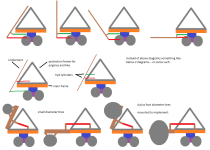

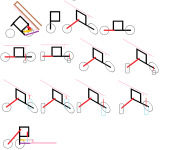

the quick hitch locking mechanism and implement ends for quick hitch. are still up in the air. of exactly what they may look like. and more of a concept thought. and no actual design to them as of yet.

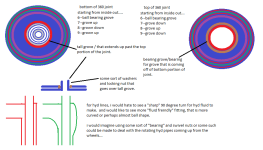

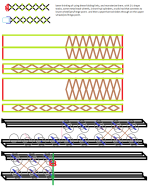

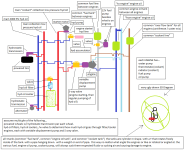

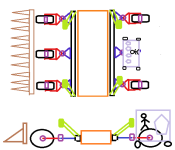

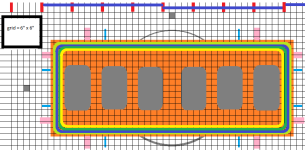

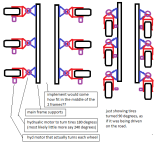

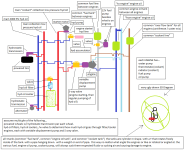

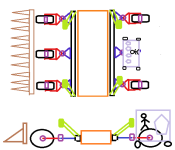

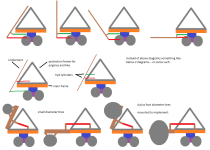

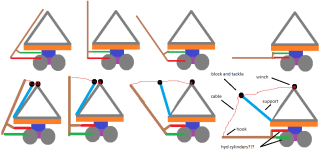

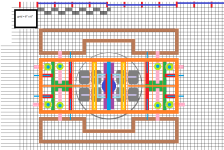

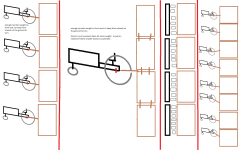

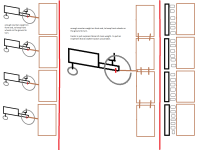

went through 360 joint. but not really drawn out fully and attempted to fit into the small space for the motor that spins the 360 joint. see posts 90 to 94 for more info on 360 joint. more specifically the special fitting to get between rotating wires... not real sure about the actually how the 360 joint will go together. i kinda went into it, and then left it as is... without redrawing and rechecking..., re thinking about it.

redid cylinder to cylinders for moving wheels back and forth under the machine. though not much detail on them yet.

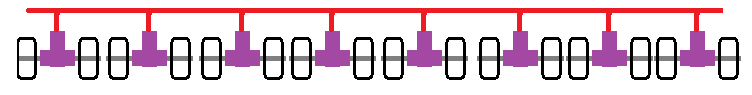

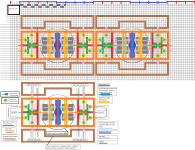

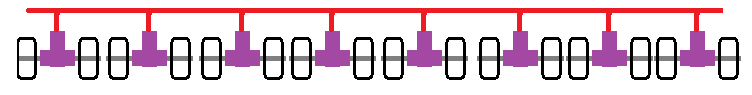

started to get into various implements but early doings on them... and more currently mind set of looking at various implements and ways that might work for various implements but more chicken scratch drawings. to get a broad over view of how things might work and attach.

still undecided / unsure what would be the primary source for this machine, drive shafts and gearing, electricity, or hyd oil. just really not there yet....

===============

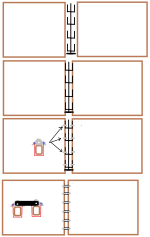

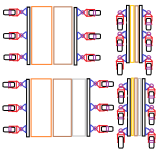

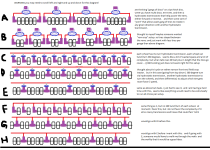

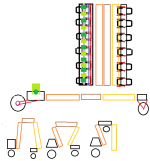

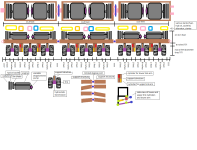

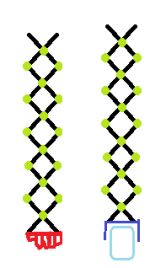

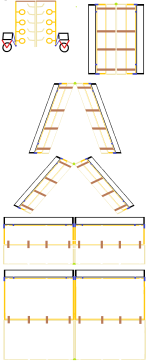

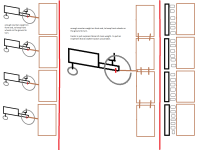

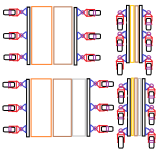

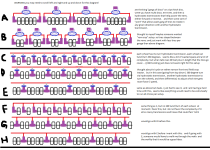

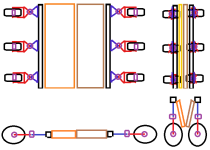

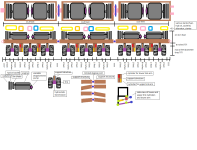

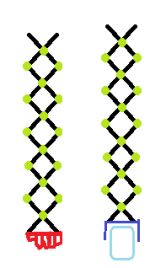

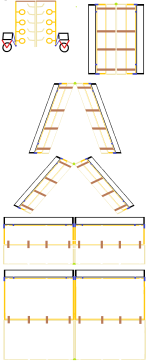

i want to go take another looking at the wheels and the "dead man circle" and look at "tracks" and perhaps transport wheel combination. and possibly loosing the 360 joint and redistributing weight cylinders. that i doubt loosing them will happen. also want to look at a 2 long tracks, and then 2 shorter tracks, (1 long, 1 short) per side of transmission/motors

or going with 4 or 8 short tracts were tracts act like caster wheels, and loosing the primary 360 joint and redistributing weight cylinders (possibility).

along with possible some sort of "suspension" or rather something that might allow the wheels or tracks in this case to slightly lean side to side backwards and forwards just a couple inches. just enough so as to keep all tires or tracks firmly on the ground across the entire width of the tire or track.

at moment kinda thinking if i went with tracks for (field mode) and then a tire on each side for (transport mode). i might be able to reduce the dead man circle. by another couple inches or a couple feet perhaps...

..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..

..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..  ..

..