boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,829

- Location

- Trivoli, IL

- Tractor

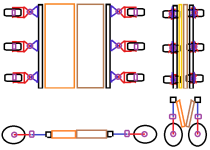

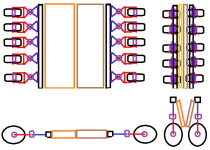

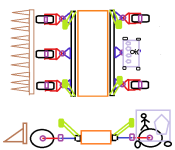

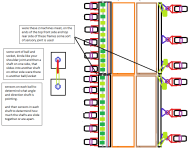

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

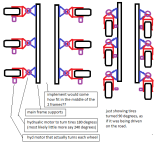

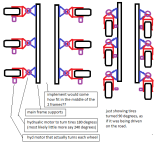

superfly got me thinking on his "mini tracked" thread on project forum about various hydrualics. and started thinking about all the super sized tractors now a days. you have this huge honking engine, massive tires and amount of tires, and then this most likely bat wing or like implement behind the tractor for field work. and then you have width limits on road ways to deal with. and as more and more power happens with engines wider implements get made.

started looking at various hydrostatic transmissions, various types of hydraulic pumps. and no need for direct shaft to gear to pulleys needed between engine and wheels. but just some hoses or some paths for hyd oil to flow in either or direction.

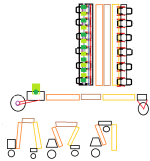

i got looking at some zero turns and use of double hydrostatic transmissions, thought about "power trac" tractors along with articulated steering.

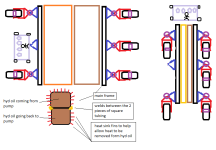

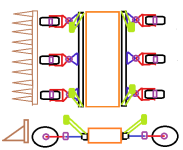

and started wondering why is there need for a typical "pulling rig" out in front, and then this huge implement in the rear. once you get into the larger class cat 2 to cat 3 implements most of them already have a full set of hydraulic cylinders to deal with fold-able wings, to deal with raising / lowering road gear. and possibly some other sort of hydraulics on the implement.

so started brain storming, of how to create a "powered implement" were you could interchange implements used. and then figure out how to make interchangeable implements, to use the same "engine / tires"

other words. engine, transmissions, tires, are all on implement. and there is no front "main machine"

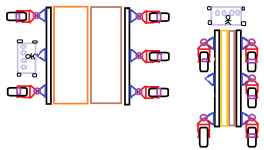

after seeing tires turned 90 degrees ,thought well duh. lets move the hyd motor for each tire, directly into the rim of each tire. this allowing tires to pivot more without sticking out further into road way, or nocking into the main frame.

================

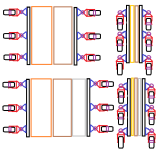

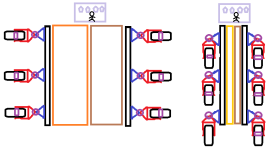

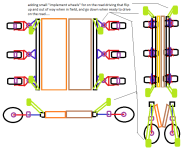

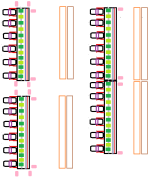

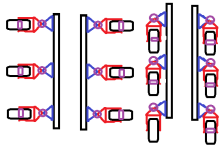

showing say "plow, disc" in top diagrams then say... (plow, disc, harrow) in bottom diagram.

left side folded out, and right side folded up for say moving to another field on the road. *shrugs*

started looking at various hydrostatic transmissions, various types of hydraulic pumps. and no need for direct shaft to gear to pulleys needed between engine and wheels. but just some hoses or some paths for hyd oil to flow in either or direction.

i got looking at some zero turns and use of double hydrostatic transmissions, thought about "power trac" tractors along with articulated steering.

and started wondering why is there need for a typical "pulling rig" out in front, and then this huge implement in the rear. once you get into the larger class cat 2 to cat 3 implements most of them already have a full set of hydraulic cylinders to deal with fold-able wings, to deal with raising / lowering road gear. and possibly some other sort of hydraulics on the implement.

so started brain storming, of how to create a "powered implement" were you could interchange implements used. and then figure out how to make interchangeable implements, to use the same "engine / tires"

other words. engine, transmissions, tires, are all on implement. and there is no front "main machine"

after seeing tires turned 90 degrees ,thought well duh. lets move the hyd motor for each tire, directly into the rim of each tire. this allowing tires to pivot more without sticking out further into road way, or nocking into the main frame.

================

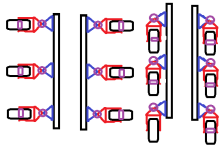

showing say "plow, disc" in top diagrams then say... (plow, disc, harrow) in bottom diagram.

left side folded out, and right side folded up for say moving to another field on the road. *shrugs*