Shield Arc

Super Member

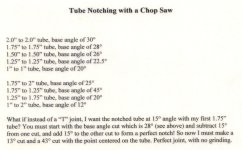

I don't ever remember saddling pipe with a chop saw, but I know guys who have great success at it. Someone posted this chart years ago who saddles with a chop saw.

Here is a link to a handy coping calculator.

Tube Coping Calculator

Here is a link to a handy coping calculator.

Tube Coping Calculator