jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

Nice to hear Lowe's is giving discounts. I wonder if it's a local thing, or if they are becomeing more contractor friendly. I've received discounts when buying from them, but it's hit or miss, and nowhere near 20%!!!!

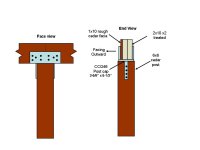

On you diagram, when you say stringer, is that going to be a header type beam with two dimensional pieces of lumber and plywood between them? or a gluelam type beam? The 3 1/2 inch width has me confused. The run is short enogh that a gluelam would work, but it would have to be protected, or treated to withstand the elements.

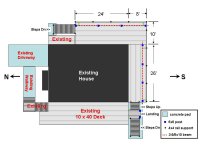

I'm also curious about yoru post placement at the corner of the building, where the two new decks come together. It sort of looks like you have extneded the support beam past the post and cantelevered it out to where you will have to run your suports for the outside corner of the deck. If that post was lined up with the outside edge of the house, then you would have direct support for that beam and joists. If you can eliminate a cantelevered attachement for a main, load bearing beam, I would sure do so.

Eddie

Eddie, thanks so much for posting to comment on my deck. I take your suggestions very seriously. I only wish you were close enough to make it possible for me to hire you to do the job.

Lowes has a policy of putting thier orders over $2000 into their quote system. Within 24 hours (most times less) you get a qoute on your materials that is competitive and a big savings over retail price. Some things are not so much discounted and others are up to 30% less. My overall savings on my BOM was 19.7%. For the average homeowner, that's a bundle. Not only was my order discounted, but everyone behind the commercial orders desk seemed genuinely interested in helping me. I'm sure the fact that I gave them an organized list of materials with part numbers included was also in my favor. All they had to do was go down my list and enter the data. I think they only had to look up the UPCs on about 6 items.

My "stringer" beam dimensions at 3-1/2" should have you confused.

I think you are dead right that I need 4 posts on the south side deck instead of 3. That will allow me to go 8-1/2'-8-1/2'-8-1/2' center-to-center between the posts and put them all the way to the corners of the deck. I have extra posts and extra Simpson brackets, so I'm okay with changing the design a bit. Thank you very much for making that suggestion. I'm much happier with the extra post and stronger structure. Great suggestion!

I also believe that I don't need 6x6 posts under the landing for the steps at the end of the existing deck. I might be better served to use 4x4 cedar posts there. 6x6 posts might look a little "chunky." What do you think?

Again, thanks for your suggestions. I'm all ears.