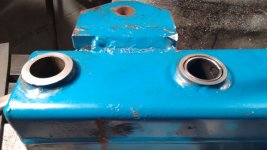

Job is now complete ... all in all, two new swivel (spherical bushings)s in the main boom, new pins on all pivot points, all pivots, including bucket, bored and new spring bushings installed. Made six of the pins, bought two, bought about a dozen bushings, the two spherical bushings and some small hardware .... total cost excluding the new boring bar I had to buy ... was about $300. Labor 10-12 hours, much of it was spent fixturing the booms in the mill, and doing the boring. I would suggest a 4" boring head and the largest boring bar that will fit in the hole because some of the holes are 5+ inches deep. Although a 3" head and a carbide insert with a small (sharp) radius seems to work too.

After assembly there is pretty much zero slop in the boom when full extended ... maybe 1/8" inch if you are very precise watching boom/tractor movement. Previously it was about 4" at the end of the boom. Overall it turned out better than I thought, and was slightly less of a PITA than I thought it would be. Broke one fitting during hose removal, $3 for a new one, found one missing swivel fitting $3. Replaced all the fluid and filter (don't use the Fram P1654A equivalent of a WIX 51553 as the Fram tries to bottom out on the filter housing ... it will work, but needs to be tightened too far).

Other than the valve body feeling like it needs a bit of a tune up .... relief valve seems a bit weak, check valves bypassing a tad, and shock dampening valves seem a bit sticky ..... it's almost as good as new. At some point I'll have to bother the experts here about the possibility of adjusting the relief valve a small amount (if possible), and the steps and/or possibility of rebuilding some of the valves. But ... still the hoe is very usable, quite controllable, delicate work not a problem.

All in all .... considering this would probably have run up a $2500 bill at a shop .... I think it was worth it.