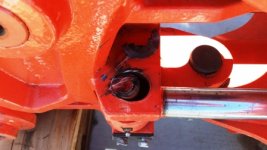

If you buy equipment anywhere, especially an auction, you are lucky if that wore out pin boss and rigged up wiring is all you find.

Alot of rental companies run stuff till their unskilled mechanics can't patch it anymore, then auction it off.

I have almost give up on renting stuff because of how crappy it is when you pick it up.

Some companies are way better-they usually rent cranes and bucket trucks.

The majority of equipment (and work vehicles) I have seen are treated with very little care. Run it till it stops, then patch together as quick as possible to continue making money.