lowerthanu

New member

- Joined

- Jun 2, 2007

- Messages

- 9

Hey guys,

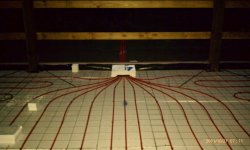

I have been a member here for years and always just have read other posts, but now have a question I need your advise on. I just bought a new house that has an existing 30x60x9 Cleary pole building on the property. It is only a few years old and in great shape. I am working on finishing it to make it my shop. Right now it is a bare building with a dirt floor. Next week I have concrete going in with full insulation under it and tubing for in floor heat. My question is regarding insulation. I have been reading up on it for several weeks on various forums and have come to the conclusion that everyone has a different opinion on how to do it.

I live in Minnesota where it gets hot in the summer and below zero in the winter. The building will be heated 24/7 via in floor heat in the winter and it will have air conditioning that will be used periodically in the summer. From what I understand spray foam insulation is the best way to go. I got a quote on it for $8500 for 2.5" in the walls and 3" sprayed on the underside of the ceiling. This is more than I am willing to spend so looking at the alternatives. Here is my game plan.

Frame out between the posts to run R19 5.5 thick" faced (so I can staple into place verticallly) bat insulation in the walls with a vapor barrier towards in inside of the building and sheeted with steel. The inner wall framing will give approximatly 1.5" of clearance between the exterior steel and the insulation. A few questions regarding this. I have heard some people talk about putting tyvak house wrap stapled on the girts and poles to block condensation from coming in contact with the insulation but allowing the interior of the walls to breath. Any thoughts on this?

Also some people have talked about putting 1.5" pink foam between the girts covering the exterior steel? Is this necessary or a worthwile idea?

For the ceiling I intend to put a vapor barrier up, then steel and have blown in insulation done on top. This seems like the best way to go, but my question is on venting. The building has no soffits on any side as there is no overhang. The roof has 2 8.5' long ridge vents on it. The gable wall runs up inside the trim so there is some air movement but no vents. My question is will this be enough venting or do I need to add a gable vent on each side, or is there something else I should do?

Thanks in advance and sorry for the lengthy post.

I have been a member here for years and always just have read other posts, but now have a question I need your advise on. I just bought a new house that has an existing 30x60x9 Cleary pole building on the property. It is only a few years old and in great shape. I am working on finishing it to make it my shop. Right now it is a bare building with a dirt floor. Next week I have concrete going in with full insulation under it and tubing for in floor heat. My question is regarding insulation. I have been reading up on it for several weeks on various forums and have come to the conclusion that everyone has a different opinion on how to do it.

I live in Minnesota where it gets hot in the summer and below zero in the winter. The building will be heated 24/7 via in floor heat in the winter and it will have air conditioning that will be used periodically in the summer. From what I understand spray foam insulation is the best way to go. I got a quote on it for $8500 for 2.5" in the walls and 3" sprayed on the underside of the ceiling. This is more than I am willing to spend so looking at the alternatives. Here is my game plan.

Frame out between the posts to run R19 5.5 thick" faced (so I can staple into place verticallly) bat insulation in the walls with a vapor barrier towards in inside of the building and sheeted with steel. The inner wall framing will give approximatly 1.5" of clearance between the exterior steel and the insulation. A few questions regarding this. I have heard some people talk about putting tyvak house wrap stapled on the girts and poles to block condensation from coming in contact with the insulation but allowing the interior of the walls to breath. Any thoughts on this?

Also some people have talked about putting 1.5" pink foam between the girts covering the exterior steel? Is this necessary or a worthwile idea?

For the ceiling I intend to put a vapor barrier up, then steel and have blown in insulation done on top. This seems like the best way to go, but my question is on venting. The building has no soffits on any side as there is no overhang. The roof has 2 8.5' long ridge vents on it. The gable wall runs up inside the trim so there is some air movement but no vents. My question is will this be enough venting or do I need to add a gable vent on each side, or is there something else I should do?

Thanks in advance and sorry for the lengthy post.