You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Preventing tractor back flip

- Thread starter retiredmgn

- Start date

- Views: 61462

More options

Who Replied?

/ Preventing tractor back flip

#161

LD1

Epic Contributor

IF the tractor has enough power to go past the equillibrium point I illustrated, AND the tires move backwards as you suggest, How exactally do they move backwards????

Are they slidding? (loss of traction) which whould result in the front comming down.

Or are they rolling backwards? IF so, How? with the clutch engaged, arent you trying to drive them forward? How do they go backwards? Lack of power?Clutch slippage?

Once you pass the equillibrium point, the forces trying to set the front down are een greater. Just the shear weight of the front in the air, plus the chain pulling on the drawbar.

The tractor DOES rotate around the axle, up to the equillibrium point. Because up to that point, the tractor is NOT moving backwards. If you care, do your little drawing again, with the chain and drawbar in a straight line (what I am calling equillibrium) and WITHOUT the rear tire moving backwards, and see where the point of rotation is???

Using the rear axle as a pivot, the whole tractor becomes like a lever. with the front wheels in the air, a rearward pulling force on the drawbar is going to try to set them back down.

Are they slidding? (loss of traction) which whould result in the front comming down.

Or are they rolling backwards? IF so, How? with the clutch engaged, arent you trying to drive them forward? How do they go backwards? Lack of power?Clutch slippage?

Once you pass the equillibrium point, the forces trying to set the front down are een greater. Just the shear weight of the front in the air, plus the chain pulling on the drawbar.

The tractor DOES rotate around the axle, up to the equillibrium point. Because up to that point, the tractor is NOT moving backwards. If you care, do your little drawing again, with the chain and drawbar in a straight line (what I am calling equillibrium) and WITHOUT the rear tire moving backwards, and see where the point of rotation is???

Using the rear axle as a pivot, the whole tractor becomes like a lever. with the front wheels in the air, a rearward pulling force on the drawbar is going to try to set them back down.

IF the tractor has enough power to go past the equillibrium point I illustrated, AND the tires move backwards as you suggest, How exactally do they move backwards????

Are they slidding? (loss of traction) which whould result in the front comming down.

Or are they rolling backwards? IF so, How? with the clutch engaged, arent you trying to drive them forward? How do they go backwards? Lack of power?Clutch slippage?

Once you pass the equillibrium point, the forces trying to set the front down are een greater. Just the shear weight of the front in the air, plus the chain pulling on the drawbar.

The tractor DOES rotate around the axle, up to the equillibrium point. Because up to that point, the tractor is NOT moving backwards. If you care, do your little drawing again, with the chain and drawbar in a straight line (what I am calling equillibrium) and WITHOUT the rear tire moving backwards, and see where the point of rotation is???

Using the rear axle as a pivot, the whole tractor becomes like a lever. with the front wheels in the air, a rearward pulling force on the drawbar is going to try to set them back down.

Not sure I can explain how/why it goes backwards. But it does. Think of it like this: If there is enough power/traction to move the system at all when it's absolutely restrained - which since we've seen tractors pull wheelies from pulling loads we know at least some of them do - then the torque available from the engine is enough to make the pinion gear start climbing the stationary ring gear. This brings the front of the tractor up, takes the drawbar end down, and by necessity starts wrapping the tractor backwards. So now the ring gear itself is slowly turning backwards, but no matter, there is plenty of torque for the pinion to keep climbing it.

Your right that the further it wraps itself, because of the design/location of the drawbar end, it becomes harder and harder to do it. Perhaps most tractors are designed such that their power/weight/geometry create a limit such that the engine will stall before it gets far enough back to flip. But assuming enough power and traction, which is what I've said all along, it will continue to wrap itself over. The only geometric condition that can prevent it is having the load vector pointing below the contact patch of the tires. Which is consistent with what I've been saying all along: The only things that prevent the flip are lack of power, lack of traction, or the resisting load vector pointing below the contact patch of the tires.

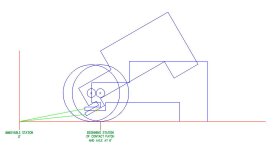

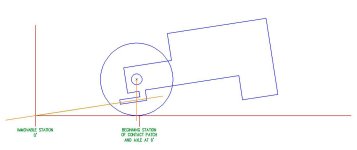

Here is my drawing angled such that the chain and drawbar create a straight line - ie. the longest possible scenario - please note that the tractor itself has backed up even to get to this point. I did not change the length of the chain at all. It can't be denied that the tractor must move backwards assuming any typically manufactured geometry.

Attachments

RoyJackson

Rest in Peace

- Joined

- Nov 17, 2001

- Messages

- 24,646

- Location

- Bethel, Vermont

- Tractor

- John Deere 4052R Cab,, Deere 855D UTV, Z920A Zero Turn Mower and assorted implements

Your mistake is suggesting that this component will somehow outweigh all the other component forces in action during the pull and prevent the front of the tractor lifting. It just won't, unless the overall load vector points below the contact patch of the tires as I've described already. This fact is true no matter the exact length or height of the drawbar or the connection details of how and where it mounts to the frame of the tractor.

xtn

Although I think we'll have to agree to disagree...what other components are you discussing? Traction? Weight? Pulling speed? Others?

Although I don't think any of these would overcome the forces I described in my previous post, my assumptions were (for sake of discussion) a straight pull on level ground. I can't make any assumptions about traction since soil conditions vary too much and I don't know enough about tractor tire traction on any given soil type. But I do believe the tires would slip first.

(EDIT: Reading your response to LD1, you assume the tires don't slip. That would likely be an erroneous assumption. And, your comment about "The only things that prevent the flip are lack of power, lack of traction, or the resisting load vector pointing below the contact patch of the tires" describes a theoretical situation more so then real world scenarios.]

As I wrote early on, I've never heard or read of any rear roll overs when pulling a load using the draw bar on level ground...never even read of a tractor rearing up...not on level ground. Closest one I'm familar with was a guy skidding a tree trunk upslope. It was a local guy (didn't know him personally) operating an old Ford or something like that.

Other then that one...no others that I'm aware of...do you have any examples you can share or link to?

RoyJackson

Rest in Peace

- Joined

- Nov 17, 2001

- Messages

- 24,646

- Location

- Bethel, Vermont

- Tractor

- John Deere 4052R Cab,, Deere 855D UTV, Z920A Zero Turn Mower and assorted implements

All the bla, bla, hook up point, length of chain. on & on. None of this BS matters.

Simple fact. if there is enough horse power & traction, a tractor cam or will go over back wards.

But do you know of any stock tractors that meet those two criteria?

BTW, another thing to complicate this discussion is front ballast...keeping it simple, front suitcase weights. BTW, I'm talking stock tractors...not machines designed for tractor pulls.

I'm sure a trained technician could show all kinds of scenarios using a 3D CAD system that can animate the situations. And, in theory, a rear roll over is possible with the right variables factored in...probably the same variables that tractor designers factor in to design preventative measures.

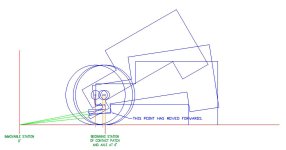

Okay here is an overlay of all three conditions. Note that the drawbar itself HAS moved forwards at your "equilibrium" point, because like you said the straight line allows the longest distance. But also note that since the axle is above the drawbar, it and the wheels attached to it have moved backwards. Of course how much it does so depends on the geometry of the bar in relation to the axle. I just eyeballed my etchasketch tractor here, but I think it's fair to say it represents typical geometries reasonably enough.

So we know that the tractor can begin to wind itself backwards. And we know that passing your "equilibrium" point will definitely increase the effort required. But if there is enough power to overcome that increased effort, the tractor can keep winding itself up.

xtn

So we know that the tractor can begin to wind itself backwards. And we know that passing your "equilibrium" point will definitely increase the effort required. But if there is enough power to overcome that increased effort, the tractor can keep winding itself up.

xtn

Attachments

But do you know of any stock tractors that meet those two criteria?

You weren't asking me, but I would like to answer that question for myself just so we're all clear...

I don't know one way or the other. I've never said a tractor will flip. I've only said what I think are the conditions that will prevent it from happening, defended my thoughts, and debated conflicting information when I could.

xtn

PS - I also want to say that I hope nobody finds my arguing to be rude. It's simply interesting debate as far as I'm concerned. I hope some may find me to be consistent, clear, intelligent, and able to back up my points. Am I always right? No, of course not. But I am always stubborn!

RoyJackson

Rest in Peace

- Joined

- Nov 17, 2001

- Messages

- 24,646

- Location

- Bethel, Vermont

- Tractor

- John Deere 4052R Cab,, Deere 855D UTV, Z920A Zero Turn Mower and assorted implements

You weren't asking me, but I would like to answer that question for myself just so we're all clear...

I don't know one way or the other. I've never said a tractor will flip. I've only said what I think are the conditions that will prevent it from happening, defended my thoughts, and debated conflicting information when I could.

xtn

PS - I also want to say that I hope nobody finds my arguing to be rude. It's simply interesting debate as far as I'm concerned. I hope some may find me to be consistent, clear, intelligent, and able to back up my points. Am I always right? No, of course not. But I am always stubborn!

Although I try to support my post through logic and clear thinking...sometimes I use a big stick to get another's attention. And sometimes even logical discussions get heated. That's when the players have to step back and agree to disagree.

Although I think we'll have to agree to disagree...what other components are you discussing? Traction? Weight? Pulling speed? Others?

Sorry, when I said components I was talking about component forces; the shear load on a particular bolt, for example. You brought up the downward forces that might be measured where the drawbar attaches to the frame. I was trying to point out that none of many component forces matter; they all are part of the net sum forces anyway.

Yup I believe tires are likely to slip first too. That satisfies my condition #2, lack of traction. That's real world, isn't it? You said you believe the tires would slip first, then accuse my conditions, which include that possibility, of being more theoretical than real world? I don't get the logic there. You say you think the tractor won't flip because the tire will slip first in the real world. I said the tractor can flip unless - among other limits - there isn't enough traction. So we've said the same thing but you're real world and I'm not?Although I don't think any of these would overcome the forces I described in my previous post, my assumptions were (for sake of discussion) a straight pull on level ground. I can't make any assumptions about traction since soil conditions vary too much and I don't know enough about tractor tire traction on any given soil type. But I do believe the tires would slip first.

(EDIT: Reading your response to LD1, you assume the tires don't slip. That would likely be an erroneous assumption. And, your comment about "The only things that prevent the flip are lack of power, lack of traction, or the resisting load vector pointing below the contact patch of the tires" describes a theoretical situation more so then real world scenarios.]

In my post to LD1 I assumed the tires don't slip only so we can explore what happens further. If the tires slip it's a no-go exercise, so for purposes of seeing what happens I make the tires non-slipping. I said IF there is enough power/traction... THEN xyz will happen. That doesn't mean I've gone back on my original statement of 3 conditions that prevent the flip.

xtn

LD1

Epic Contributor

Okay here is an overlay of all three conditions. Note that the drawbar itself HAS moved forwards at your "equilibrium" point, because like you said the straight line allows the longest distance. But also note that since the axle is above the drawbar, it and the wheels attached to it have moved backwards. Of course how much it does so depends on the geometry of the bar in relation to the axle. I just eyeballed my etchasketch tractor here, but I think it's fair to say it represents typical geometries reasonably enough.

So we know that the tractor can begin to wind itself backwards. And we know that passing your "equilibrium" point will definitely increase the effort required. But if there is enough power to overcome that increased effort, the tractor can keep winding itself up.

xtn

Well, I still fail to see the logic of your "pivot point" and the whole "tractor moving backwards" theory.

I guess I could take it and use that to my advantage as to how the tractor CANNOT flip backwards.

For starters, the tractor, when unstable in the front to rear direction, can only pivot around two points. The front and rear axles. Just because in your "theory" the tractor moves rearward, does NOT change the pivot point of the tractor. Kinda like a wheelbarrow. Everyone knows the pivot is around the front wheel. Just because you simultaneously lift and start moving at the same time doesnt magically change the pivot point.

And second, since you illustrated so well, that the tractor MUST move backwards in order to keep rotating upward, kinda proves that you cannot flip from the drawbar. Because engine is running forward, coupled to transmission rinning forward, coupled to rear-end tryint to turn the tires forward. The ONLY ways for it to actually move backwards would be:

1. for it to break traction, and you will not flip without traction...or

2. Engine spins backwards...unlikely unless you had a ton of momentum (20mph runnign start)...or

3. Clutch to slip, which would result in not enough power to transfer for a flip to occure.

So to sum it up, your drawings are spot on, but just like the chain being hooked to an immovable object, the tires are coupled to unlimited HP engaged in FORWARD, thus it is impossible (in theory) for the tires to spin backwards while being under power in the forward direction.

And I hate this whole pinion climbing the ring gear termoniology as well. I heard it a lot in my college days as well in the HP chassis building classes. (which actually made a little more since in that field, because a susension allows the rear end a little independent movement from the rest of the vehichle), but we are dealing with a tractor here. People act like the pinion is a seperate part of the tractor and can do what it wants. It cant. It is coupled to the tractor. If the pinion goes up, the front goes up, If the front CANT go up, the pinion CANT climb PERIOD. Sure, I guess you could say it is trying to climb, but I guess you could also say that the back tires are trying to run over the rest of the tractor too.:confused2:

RoyJackson

Rest in Peace

- Joined

- Nov 17, 2001

- Messages

- 24,646

- Location

- Bethel, Vermont

- Tractor

- John Deere 4052R Cab,, Deere 855D UTV, Z920A Zero Turn Mower and assorted implements

Sorry, when I said components I was talking about component forces

I knew what you meant...I used the term "factors" instead, that's all.

eray1066

Bronze Member

- Joined

- Jun 2, 2009

- Messages

- 74

- Location

- RI, MA

- Tractor

- Challenger MT285B, Kubota L4150 , Farmall super A, Farmall Cub

Logic and reality can collide powered by torque. This video of a tractor pull demonstrates a wheelie with the chain attached behind and below the axle as can be seen at the end of the video.

I have had the front end of a tractor come off the ground many times in the course of 50 years of operating machines many of them with the chain or cable well below the axle (some ) Geometry aside the power of the tractor can overcome the front end weight

I have had the front end of a tractor come off the ground many times in the course of 50 years of operating machines many of them with the chain or cable well below the axle (some ) Geometry aside the power of the tractor can overcome the front end weight

SPYDERLK

Super Star Member

- Joined

- Feb 28, 2006

- Messages

- 12,569

- Location

- VA

- Tractor

- JD2010, Kubota3450,2550, Mahindra 7520 w FEL w Skid Steer QC w/Tilt Tatch, & BH, BX1500

Traction is the key, [If your tractor can get enough traction it will flip, if the tires spin it will not.] The lower the attach point the more traction required to overcome.

Larry...do you design tractors? Do you...other then theory, know anything about tractor design and the dynamics involved?

Although I'm in Quality Assurance (not design...automotive and (currently) aerospace, but not tractor specifically), I did a fair amount of study on safe usage of a tractor as I didn't want to become an unfortunate statistic. Does that make me an expert on tractor design...nope...but it does make me a very knowledgeable owner of tractors.

As far as your previous threads...once they're off the first page of a forum...I doubt anyone reads or has knowledge of them (BTW, that applies to all posters, not just you). This topic has gone on (now and then) for at least 10 years...sort of like the "HST vs. Gear" debates.

NO! You seem to be missing an extremely important nuance ... You can apply infinite force at a ground level pull point and the tractor wont tip at all. The front end wont even lighten. The thing about a fixed drawbar is that the pull point starts a foot or more high, but as the tractor starts to tip back the pull point goes lower and lower. Finally the end of the drawbar reaches ground level and no amt of force from traction will continue the tip. This fact is developed in previous threads and was linked earlier. Starting over at 0, xtn is doing a good job, but probably dont know nuttin about whats really going on cuz he doesnt design tractors. Im going to take a look at LD1s stuf now. Im sure its good, but also cursed by lack of specific tractor design experience.

larry

RoyJackson

Rest in Peace

- Joined

- Nov 17, 2001

- Messages

- 24,646

- Location

- Bethel, Vermont

- Tractor

- John Deere 4052R Cab,, Deere 855D UTV, Z920A Zero Turn Mower and assorted implements

NO! You seem to be missing an extremely important nuance ... You can apply infinite force at a ground level pull point and the tractor wont tip at all. The front end wont even lighten. The thing about a fixed drawbar is that the pull point starts a foot or more high, but as the tractor starts to tip back the pull point goes lower and lower. Finally the end of the drawbar reaches ground level and no amt of force from traction will continue the tip. This fact is developed in previous threads and was linked earlier. Starting over at 0, xtn is doing a good job, but probably dont know nuttin about whats really going on cuz he doesnt design tractors. Im going to take a look at LD1s stuf now. Im sure its good, but also cursed by lack of specific tractor design experience.

larry

Actually, xtn is making more sense (even though I disagree with some of his assumptions) then you are...

I'm guessing you're an armchair engineer without much real world experience.

Anyway, now this topic is going in circles...

Egon

Epic Contributor

Well folks there seem to some new math involved here. Now I didn't get schooled with the new math so.

But I'm quite positive that when sitting on the seat of the Farmall H and pulling stumps I'f I didn't disengage the clutch as the front wheels were lifting my Father would have been exceeding mad about having to get the tractor put back on it's wheels and get all the sheet metal and other assorted things fixed.:thumbsup::thumbsup::thumbsup:

Equilibrium gets reached when the muffler is broke off and the top of the hood is making contact with the ground.

But I'm quite positive that when sitting on the seat of the Farmall H and pulling stumps I'f I didn't disengage the clutch as the front wheels were lifting my Father would have been exceeding mad about having to get the tractor put back on it's wheels and get all the sheet metal and other assorted things fixed.:thumbsup::thumbsup::thumbsup:

Equilibrium gets reached when the muffler is broke off and the top of the hood is making contact with the ground.

crash325

Elite Member

But do you know of any stock tractors that meet those two criteria?

BTW, another thing to complicate this discussion is front ballast...keeping it simple, front suitcase weights. BTW, I'm talking stock tractors...not machines designed for tractor pulls..

(" I guess I could take it and use that to my advantage as to how the tractor CANNOT flip backwards. ")

Old Ford's & Fergi's were pretty well know for being able to go over backwards. Yes I have seen one go over backward. On a slight slope, using a sickle bar mower. - I took a neighbor to go get his old Fergi. The first time he tried to move it, he added throttle (Not a lot, maybe a 1/4? ), then let the clutch out. "Wrong" By the time he got the clutch back in the front wheels were 2 feet off the ground. Yes Front Ballast would really help, tried to get the neighbor to add some, but he was afraid it would be hard to steer.

If you have a brush hog, Gannon or similar on the back, that will stop the machine from going over back wards.

Now lets talk about "Going over Forward". :laughing:

Can a tractor go over on the front wheels. If you have a FEL it can only go so far. In 4WD my New Holland will lift the rear wheels if loaded real heavy. Not to scary until it gets a little sideways and onto 1 wheel. :laughing: Yep I been there. - Deere 210 has enough FEL lift to pick the rear wheels, even with a Gannon on the back. - Rounder (Bobcat) has enough lift to pull you over onto the bucket. Had a tilt trailer for the Rounder, backing off that trailer was a fun ride, when the trailer tilted you knew you were going over backward. It never did, but I never got over the feeling it was going to.:laughing:

Skidding the rock in the picture had me on 2 front wheels more than once and on 1 wheel once. It has to weigh a little over 3,000#s as the FEL will lift 1 end very slowly.

Another little gem of advice.

Attachments

SPYDERLK

Super Star Member

- Joined

- Feb 28, 2006

- Messages

- 12,569

- Location

- VA

- Tractor

- JD2010, Kubota3450,2550, Mahindra 7520 w FEL w Skid Steer QC w/Tilt Tatch, & BH, BX1500

Visualize ... When the drawbar does not extend back beyond the tire circle it wont reach the ground hence infinite traction at ground level will overpower the shorter lever and the tractor will tip over backwards. The back axle will be moving backwards and the tires will be rolling back toward the load along with the tractor. Thruout the tip the axle will turn appropriately wrt tractor to make up for the proportional difference between the tire radius and the changing lever presented by the drawbar. With a long drawbar the tractor would rear up [moving backward] until the drawbar touched down. Then infinite force could be applied and the entire earth could end up crammed between immovable load and tractor.Well, I still fail to see the logic of your "pivot point" and the whole "tractor moving backwards" theory.

.:confused2:

larry

For starters, the tractor, when unstable in the front to rear direction, can only pivot around two points. The front and rear axles. Just because in your "theory" the tractor moves rearward, does NOT change the pivot point of the tractor. Kinda like a wheelbarrow. Everyone knows the pivot is around the front wheel. Just because you simultaneously lift and start moving at the same time doesnt magically change the pivot point.

If we define a pivot point as that point about which some points move in an arc, then it's true that the pivot point is at the axle if the tires don't move. If you graph some points on the tractor as it pivots AND the whole thing is moving horizontally, you will find that the geometric pivot point of the whole tractor as a unit - relative to Earth - is somewhere else entirely. Depending on the paths generated by any given points as the tractor undergoes this movement, the geometric pivot point itself can be moving all over the place.

If the pinion can climb a stationary ring, what prevents it from climbing a slowly rotating ring? You can climb a stationary ladder. Can you not also climb a telescoping ladder at the same time it is extending? Does your climbing action necessarily and absolutely prevent the thing from extending?And second, since you illustrated so well, that the tractor MUST move backwards in order to keep rotating upward, kinda proves that you cannot flip from the drawbar. Because engine is running forward, coupled to transmission rinning forward, coupled to rear-end tryint to turn the tires forward. The ONLY ways for it to actually move backwards would be:

1. for it to break traction, and you will not flip without traction...or

2. Engine spins backwards...unlikely unless you had a ton of momentum (20mph runnign start)...or

3. Clutch to slip, which would result in not enough power to transfer for a flip to occure.

If my drawings are spot on, then your declaration of theory is not. Think about my ladder analogy. Of course I'm only right if by "spin" you mean the tires roll backwards, not if you mean they loose traction. If they loose traction we all know the tractor won't keep climbing, so this exploration must be done under the assumptions of complete traction or we might as well not even explore the possibility. I also believe my drawings are spot on, and that they represent what will actually happen under the ideal but impossible conditions of unlimited power and traction. It represents what MUST happen, regardless of our ability or lack thereof to explain it clearly. I suppose we might move things into the realm of real life possibilities if we clearly state that the tires might spin in a forward direction some while moving backwards overall and still having enough friction to offer rotational resistance at the ring gear in an amount greater than the engine power is trying to drive it forward so that the pinion climbs it. That's a long sentence. If it doesn't make sense the first time, please read it again slowly.So to sum it up, your drawings are spot on, but just like the chain being hooked to an immovable object, the tires are coupled to unlimited HP engaged in FORWARD, thus it is impossible (in theory) for the tires to spin backwards while being under power in the forward direction.

The ring doesn't climb the pinion only because there is suspension that allows movement. Sure, the ring is attached to the rest of the tractor. That's why it lifts the tractor as it climbs. Notice I said as it climbs, not as it tries to climb. Your restriction seems to be that the front of the tractor cannot come up, therefor the pinion cannot climb. The front can't come up? If you make that assumption you beg the question and render the whole exercise moot. Can a tractor flip? Heck no, it's impossible for the front end to ever come up! See what I mean? It's not a valid restriction.And I hate this whole pinion climbing the ring gear termoniology as well. I heard it a lot in my college days as well in the HP chassis building classes. (which actually made a little more since in that field, because a susension allows the rear end a little independent movement from the rest of the vehichle), but we are dealing with a tractor here. People act like the pinion is a seperate part of the tractor and can do what it wants. It cant. It is coupled to the tractor. If the pinion goes up, the front goes up, If the front CANT go up, the pinion CANT climb PERIOD. Sure, I guess you could say it is trying to climb, but I guess you could also say that the back tires are trying to run over the rest of the tractor too.:confused2:

Does that help?

xtn

Last edited:

Here are some similar links:

- Replies

- 6

- Views

- 3K

- Replies

- 5

- Views

- 10K

3-Point Hitch

Tractor Three Point Hitch CROSS-DRAWBARS

- Replies

- 18

- Views

- 28K