Joe_R

New member

Hi folks.

I'm working on a Bush Hog Squealer 148 rotary cutter.

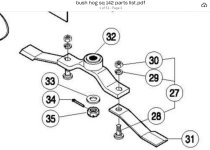

I've used an impact driver to loosen the nut on the blade attachment bolt. But after loosening about 1/8 inch, the bolt (#28 on the diagram) just spins when the nut is turned.

The head of the bolt is round, not hex. I can't figure out how to grab the head of the bolt so that I can finish loosening the nut.

It doesn't make sense that a nut to be torqued to 500# lbs, and likely difficult to remove, wouldn't have a hex head or be keyed so it would not spin. Since neither of those things are true, I'm missing something.

Anyone have any ideas how to get this nut the rest of the way off?

Thanks.

I'm working on a Bush Hog Squealer 148 rotary cutter.

I've used an impact driver to loosen the nut on the blade attachment bolt. But after loosening about 1/8 inch, the bolt (#28 on the diagram) just spins when the nut is turned.

The head of the bolt is round, not hex. I can't figure out how to grab the head of the bolt so that I can finish loosening the nut.

It doesn't make sense that a nut to be torqued to 500# lbs, and likely difficult to remove, wouldn't have a hex head or be keyed so it would not spin. Since neither of those things are true, I'm missing something.

Anyone have any ideas how to get this nut the rest of the way off?

Thanks.