bluehog

Bronze Member

- Joined

- Nov 13, 2010

- Messages

- 89

- Tractor

- New Holland TC35D 2001

I have followed several of the great threads here on rippers for some time. I know many of you have purchased or fabricated your rippers. I thought that starting a new thread would be advisable. I actually started asking this in another thread and felt that I was "high jacking" as I know I'll have more questions. Any and all input as to what has worked as well as not is what I'm looking for.

I find myself in situation that I need to remove a couple dozen stumps from my property in the New Mexico mountains. The trees are pine so I am not dealing with the hardwoods... but I still want something that is not going to need replacing. The ground is loaded with volcanic basketball sized rock in a sort of clay/caliche (sp?)soil.

My equipment is a NewHolland TC35D with Woods BH9000 backhoe.

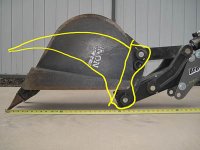

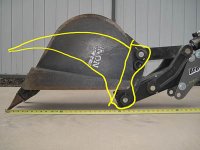

In reviewing what has been posted here and those pics that were provided, I have noticed that the relationship of the point to the locator pins seems to be different than that of the actual digging bucket.

See the photos attached to see what I am describing. In these pics I have extended my backhoe to it's fullest reach and placed the dipperstick against the ground, also the bucket is in full open position. The front teeth of the bucket do not touch the ground <1/8" above. What are the advantages or disadvantages of maintaining the point location to actual bucket design?

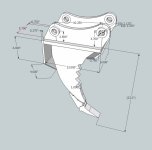

Pic 1 shows duplicating bucket location

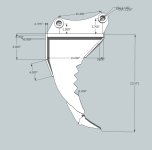

Pic 2 shows what MIE style point to locators

I find myself in situation that I need to remove a couple dozen stumps from my property in the New Mexico mountains. The trees are pine so I am not dealing with the hardwoods... but I still want something that is not going to need replacing. The ground is loaded with volcanic basketball sized rock in a sort of clay/caliche (sp?)soil.

My equipment is a NewHolland TC35D with Woods BH9000 backhoe.

In reviewing what has been posted here and those pics that were provided, I have noticed that the relationship of the point to the locator pins seems to be different than that of the actual digging bucket.

See the photos attached to see what I am describing. In these pics I have extended my backhoe to it's fullest reach and placed the dipperstick against the ground, also the bucket is in full open position. The front teeth of the bucket do not touch the ground <1/8" above. What are the advantages or disadvantages of maintaining the point location to actual bucket design?

Pic 1 shows duplicating bucket location

Pic 2 shows what MIE style point to locators

Last edited: