My point wasn't any of the above, perhaps I was a bit to brief in my last post. That list of questions is one you should ask every time before you bring a product to market. Not so that there's some pie in the sky goal, but so that you know the answers going in, and have a clear head about what your expectations should be. I've passed on licensing/building custom equipment before because the answers to those questions for that product didn't align with our company's goals.

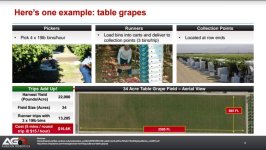

There's another consideration that I don't see mentioned anywhere. The extra worker who's job is to unload the machine at the home station. Unless you can automate that, your customer will have to both be willing to supply each field worker with a 4500 dollar device, and bring on a laborer to man the home station. For round numbers sake, lets say that each worker spends 10% of their 10 hour day going to and from the central collection point. So this 4500 dollars buys an extra hour per day per worker, or rather 4600 does, due to the five hour battery life and 100 dollar battery price I saw cited a few pages back. But there has to be somebody working at the collection hub unloading and restocking the burros, as well as pulling the dead batteries and installing the fresh ones at the halfway point. So you now have a worker who has to be on hourly wage, rather than being paid per pick, and pickers who can now earn more money from you per day. And you've spent 4600 per picker. As a farm boss I don't see the math working out unless you have an extremely time sensitive crop and an incredible shortage of workers.

Is there a market for your product? I'm sure there is. There's a market for pretty much anything. But my back of the napkin math leads me to believe it would be more expensive for the normal produce operation than hiring a dedicated collector on a small tractor/skid loader, who could work with multiple pickers at once, carry much more weight, and last more than five hours at a go.

For instance, I've seen one vineyard work harvest. They pre-stage 5 gallon buckets all along the rows. Pickers go down the rows filling the buckets as they come to them and leaving them where they were. A collector comes and gets the full buckets, empties them into bins, takes the bins back to storage, and leapfrogs past the pickers, re-staging the now empty buckets. Rinse and repeat. I have no idea if this is industry standard practices, but it seems pretty straightforward to me, and since you'd need the collection worker even with the burros...not really seeing the economics of switching.

Also, for truly industrial operations these exist.

Then there's all the other produce that has mechanical pickers already developed. Pik-rite has pickers for tomatoes, peppers, chili peppers, cucumbers, and carrots, and I'm sure there's other companies out there with units for other produce.