Rankrank1,

I interpret your lower than 50 amps statement above, to mean that you prefer to weld thinner material with DC.

I just watched this old GE presentation on AC welding, which makes AC sound like the best thing since sliced bread.

http://m.youtube.com/watch?v=CW7I-ymfINU

The film goes into great detail about how AC counteracts the effects of arc blow. Isn't arc blow what causes me to burn through thin material? Would I be able to weld thinner material with a DC stick welder than my AC machine? I've had burn through problems with both a crank adjustment AC machine made by Miller and a dial set Lincoln tombstone.

Thanks,

Stuck

No my statement is just as it reads. At less than 50 amps the perceived difference between AC and DC is going to be more noticeable to the average backyard hack. At above 50 amps the difference is much less noticeable to the average backyard hack like me in regards to accomplishing the needed work done (other than AC does sound different).

Arc blow has nothing to do with burning through metal. Arc blow usually comes from magnetized metal and it makes your arc wander all over instead of where you aim it and yes that happening can cause many issues including burn through. Lots of old farm equipment the metal becomes magnetized so to speak just from the material moving through it all the time in the same direction it can happen in factory equipment, or earthmoving equipment as well (haybalers, pan scrapers, factory conveyors, etc.). AC can possibly counteracts arc blow where DC does not.

Now as to whether you can weld thinner metal with DC arc over AC arc, then that answer is likely slightly. Remember though that stick welding is not typically for metal much thinner than say 1/16" (or 16 gauge) and even then you will need to be pretty darned decent to keep from burning through with stick. Thin metal is the specialty of a mig unit or to a lesser extent even a wire feeder with flux core. Having DC on a stick machine will allow you to switch polarity to help a tad bit with burn through and the arc is more stable at the really low amp settings so it can help a tad bit but again it is not an immense advantage.

What do I mean by switching polarity? The easiest way for me to explain that is to sorta think of it like this:

a) DC electrode + (67% of your power into the rod and 33% into the workpiece) (results in max penetration and how you will run DC the majority of the time).

b) AC There is no polarity on AC as it is continuously switching back and forth (50% of your power into rod and 50% into your workpiece).

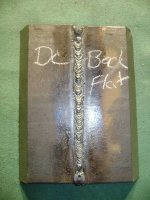

c) DC electrode - (33% of your power into rod and 67% into workpiece) (results in least penetration and is seldom used, but it can be handy if you do not have a wire feeder and using something like 6013).

The OP already has a wire feeder so anywhere that you could make an argument that DC might be the most beneficial for him is a mute point as he can simply use his wire feeder there.