good question. i will let you know in a year.

based on my reading it has chemical resistance. I guess we will see.

If you print them in nylon they should hold up. I have a nylon lathe change gear for metric threading that I printed nearly 10 years ago and it still works just fine. It comes out of an oily drawer, goes onto an oily machine where it's meshed with other oily gears, subjected to more torque than a 3D printed part should be, then put back in the oily drawer more oily than when it went in.

If you're just getting into 3D printing and you want to print something other than nick-nacks, I suppose my best tips would be:

1. Carefully consider which in axis your parts will receive the most forces, and print them oriented in such a way that that is their strongest axis. Remember that the parts have a "grain" like wood and are bound to split if subjected to the wrong forces in the wrong axis.

2. Know your polymers and use the right tool for the right job. They all have different strengths and weaknesses and there are tradeoffs for all of them, no one-size-fits-all filament is available.

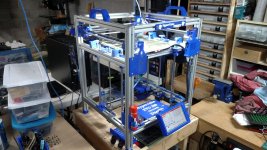

I got into 3D printing in 2013, with a bold and naive plan to build a 3D printed prosthetic hand for my dad and make it open source because bespoke prosthetics are incredibly expensive and not universally available. I quickly learned that 3D printing was not up to the task. Nobody then, and (my impression) nobody now, was interested in performing collaborative repeatable and qantifiable strength testing to come up with best practices to make functional parts. Everyone was content to print chess rooks and smash them in a vise saying "wow I got 3 good handle cranks out of that one before it exploded. Very strong part!" It's disappointing that little progress has been made on this front. I developed

a test object and

a testing procedure that I hoped could unify at least some small corner of the 3D printing community and get a few people going the same direction toward strong parts. There was zero interest.

Anyway, here's a sample of what my unending failures looked like; something suitable only for Mr. Glass:

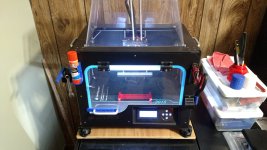

So I abandoned 3D printing and went after CNC milling. The prosthetic hand project fizzled out after a few years, not because i lost interest but because my dad did. Well, maybe I did too a bit, but mainly because I could tell he wasn't crazy about it. He went without a hand for 40 years and was pretty used to it. But, I still wanted a CNC mill so eventually I saved up enough to get one. I'm quite happy with it and only rarely do I clear the pile of debris off my 3D printer and put it to work. Every time I do, I have to put my filaments in the oven overnight because they sit so long.

3D printing is fun and exciting, and the cost of admission has come down so far that I would encourage almost anyone to give it a shot. But with a realistic understanding of its limitations. I am glad to see that you found a practical thing to make. Sadly, ideas for things like that no longer come to me as the 3D printing thought process has all but left the building.