You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Spray arc...

- Thread starter Dadnatron

- Start date

- Views: 15003

More options

Who Replied?

/ Spray arc...

#41

Dadnatron

Veteran Member

What do you mean by 'plain old MIG'?

What type of settings are you talking about?

PowerMTS 251Si with TIG Package | Everlast Generators

What type of settings are you talking about?

PowerMTS 251Si with TIG Package | Everlast Generators

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

From what you've told us so far, I think you need to find a "teacher" that's LESS in love with playing with a $6k machine you will NEVER buy or need, and MORE in love with actually TEACHING. So far, he hasn't told you about ways of holding the gun, practicing MOVING the gun BEFORE you pull the trigger, HOW and WHY you do certain things and DON'T do others, or much else that beginners SHOULD learn first.

Seriously, if I were in your shoes I'd ask for my money back - you would learn far more in less (FREE) time at weldingtipsand tricks.com....

For example, your "leaning tower of pisa" welds - welds don't "pull" much at all WHILE you're welding, it's AFTER - they're caused by SHRINKAGE, and since the side you welded got the most heat, it will SHRINK more and "pull" the welded piece to that side - sometimes DRASTICALLY, as you experienced. There are a few ways to combat that, some will help right away - others take quite a bit of experience to COMPLETELY eliminate the problem.

Some of the ways that work for me - set the piece you want at 90* to a slightly OBTUSE angle on the side your FIRST tacks will go, then quickly tack the OTHER side - keep moving your subsequent welds around, constantly checking "square" as you go, placing your NEXT weld on the "obtuse" side -

I've done a lot of projects using square tubing, and when it's possible I will HARD clamp a diagonal across 2 pieces I want SQUARE (but STILL use the "hop around" and "let it cool" tricks) - I've built several "roof frames" for portable shelters, typically 8' x 12', some 12' x 12' - using these "tricks", they are ALL less than 1/16" difference in diagonal measure. Find me a WOOD framing carpenter that can claim that

Here's one example of combatting weld pull -

http://www.tractorbynet.com/forums/welding/314087-preheat-advice-requested.html?highlight=

Jody (weldingtipsand tricks.com) will tell you to "stay at the front of the puddle" and "push" weld with MIG - those two things will get you further than most comments, and if followed religiously will keep you from "piling bird poop on top of MORE bird poop" -

There's a bunch more to this as anyone will tell you, but it all helps... Steve

Seriously, if I were in your shoes I'd ask for my money back - you would learn far more in less (FREE) time at weldingtipsand tricks.com....

For example, your "leaning tower of pisa" welds - welds don't "pull" much at all WHILE you're welding, it's AFTER - they're caused by SHRINKAGE, and since the side you welded got the most heat, it will SHRINK more and "pull" the welded piece to that side - sometimes DRASTICALLY, as you experienced. There are a few ways to combat that, some will help right away - others take quite a bit of experience to COMPLETELY eliminate the problem.

Some of the ways that work for me - set the piece you want at 90* to a slightly OBTUSE angle on the side your FIRST tacks will go, then quickly tack the OTHER side - keep moving your subsequent welds around, constantly checking "square" as you go, placing your NEXT weld on the "obtuse" side -

I've done a lot of projects using square tubing, and when it's possible I will HARD clamp a diagonal across 2 pieces I want SQUARE (but STILL use the "hop around" and "let it cool" tricks) - I've built several "roof frames" for portable shelters, typically 8' x 12', some 12' x 12' - using these "tricks", they are ALL less than 1/16" difference in diagonal measure. Find me a WOOD framing carpenter that can claim that

Here's one example of combatting weld pull -

http://www.tractorbynet.com/forums/welding/314087-preheat-advice-requested.html?highlight=

Jody (weldingtipsand tricks.com) will tell you to "stay at the front of the puddle" and "push" weld with MIG - those two things will get you further than most comments, and if followed religiously will keep you from "piling bird poop on top of MORE bird poop" -

There's a bunch more to this as anyone will tell you, but it all helps... Steve

Dadnatron

Veteran Member

Thanks Steve.

I definitely watch Jody and really like his site and YouTube channel.

And I agree about a different teacher... I'm realizing that more and more. He is a nice guy, but he has not once watched me put down a bead and I've watched him put only 2 or 3. I'm usually pretty good at self learning, but I know that there are things which I could fix... If I had some direction.

I might look around some more and see what I can find. I'm going to tell him I want to work on a 'real world machine' and do some typical MIG welding. At least if I can get something out of the class it will be better than nothing. This is a major Welding supply store in this area. It provides a large portion of products for the areas welders. I like the place... just not what I've been 'learning' thus far.

I definitely watch Jody and really like his site and YouTube channel.

And I agree about a different teacher... I'm realizing that more and more. He is a nice guy, but he has not once watched me put down a bead and I've watched him put only 2 or 3. I'm usually pretty good at self learning, but I know that there are things which I could fix... If I had some direction.

I might look around some more and see what I can find. I'm going to tell him I want to work on a 'real world machine' and do some typical MIG welding. At least if I can get something out of the class it will be better than nothing. This is a major Welding supply store in this area. It provides a large portion of products for the areas welders. I like the place... just not what I've been 'learning' thus far.

Shield Arc

Super Member

Short circuit transfer.What do you mean by 'plain old MIG'?

What type of settings are you talking about?

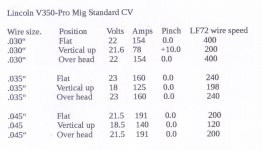

I really like Lincoln's L56 wire, with C-25 gas.

Here are the settings I use with my Lincoln V350-Pro.

Attachments

logangrey

New member

i used to do alot of spray arc back in the day. had a powcon pulse mig 035 wire and 98/2 for shielding gas. hot but was always a strong pretty weld

stuckmotor

Super Member

- Joined

- Sep 23, 2009

- Messages

- 7,641

- Location

- Lower Up State S.C.

- Tractor

- AC WD 34 hp/3500 lbs MF 261 60 hp/5380 lbs

When SA speaks, welder hacks should listen. I was sort of curious about the whole spray arc thing as well. Case closed for me.

SA told me basically the same thing he told the OP and I took it out of serious consideration as well.

Doug25

New member

i used to do alot of spray arc back in the day. had a powcon pulse mig 035 wire and 98/2 for shielding gas. hot but was always a strong pretty weld

Yes, spray with .o35 solid wire.

I have a Smith mixer and dial down the CO2 to get into spray.

So using .035 solid (s-6) wire, I can run 75/25 short arc on thin metal, change to 85/15 (or close to)

dial up the voltage and get into spray.

Very versatile set-up and I find no problems with mill scale type contamination (not serious

rust or painted by any means)

As far as metal core or gas shielded flux core for the thicker metals, I don't want

to have to change wire. I simply change (2) dials.

yomax4

Elite Member

- Joined

- Mar 11, 2007

- Messages

- 2,855

- Location

- Midwest

- Tractor

- ISEKI TA 247. Stihl Saws Gravely Zt's Polaris ATV's State Of The Art Welding Equipment

You can do most and build most anything within reason with a Hot short arc. I am surprised that there is so much discussion on spray transfer. Yes it's a smooth high deposition way to weld with low spatter providing you stay in position but. With proper technique and parameters you can do just fine with short arc. I'm not saying you should forego Spray at all. You should learn it but. If you want to get into the current millennium you should at least be curious about Pulse and Twin Pulse and what it can do for you. As mentioned above, I too have a Smith Mixer and enjoy the ease of switching from short arc gas to pulse gas as well as higher 90%+ Argon gas for Stainless. Learning to weld is a one step at a time process but if ever you want to cheat and look at the last chapter of the book before reading all of it, You'll be looking at Pulse and or Twin Pulse. They Trump Spray any day. So much fun to be interested and learning this wonderful productive skill. Good Luck going forward !!

Doug25

New member

I do all this with a 40 year old Linde SVI 400 cost me $300, I run it off my rotary phase convertor at my farm shop.You can do most and build most anything within reason with a Hot short arc. I am surprised that there is so much discussion on spray transfer. Yes it's a smooth high deposition way to weld with low spatter providing you stay in position but. With proper technique and parameters you can do just fine with short arc. I'm not saying you should forego Spray at all. You should learn it but. If you want to get into the current millennium you should at least be curious about Pulse and Twin Pulse and what it can do for you. As mentioned above, I too have a Smith Mixer and enjoy the ease of switching from short arc gas to pulse gas as well as higher 90%+ Argon gas for Stainless. Learning to weld is a one step at a time process but if ever you want to cheat and look at the last chapter of the book before reading all of it, You'll be looking at Pulse and or Twin Pulse. They Trump Spray any day. So much fun to be interested and learning this wonderful productive skill. Good Luck going forward !!

Twin pulse would cost me how much ?

And IIRC the bog standard Lincoln 255c can go spray with .035 wire.

Kinda handy to occasionally weld some thick stuff that comes into the shop

without spending time to change wires, or buy a $6k machine eh ?

I work in the heavy fabrication industry, get into several similar shops, no one I know is running twin pulse.

Spray or gas shielded flux core is what I see everyday.

yomax4

Elite Member

- Joined

- Mar 11, 2007

- Messages

- 2,855

- Location

- Midwest

- Tractor

- ISEKI TA 247. Stihl Saws Gravely Zt's Polaris ATV's State Of The Art Welding Equipment

I do all this with a 40 year old Linde SVI 400 cost me $300, I run it off my rotary phase convertor at my farm shop.

Twin pulse would cost me how much ?

And IIRC the bog standard Lincoln 255c can go spray with .035 wire.

Kinda handy to occasionally weld some thick stuff that comes into the shop

without spending time to change wires, or buy a $6k machine eh ?

I work in the heavy fabrication industry, get into several similar shops, no one I know is running twin pulse.

Spray or gas shielded flux core is what I see everyday.

Yes sir, Process and application will vary all over the country. Pulse and twin pulse are newer processes that will be the norm in a few years. Kinda futuristic sounding arc as well. I do remember the old Linde yellow face machines and later the white face, Many still in operation where I live. You got yours for $300. Can't argue. Probably last another 30 years or more. You could get into a nice Pulse/Twin Pulse set up for between 4-8K depending who you bought it from. What a deal ayy?

Sodo

Elite Member

- Joined

- Apr 21, 2012

- Messages

- 3,311

- Location

- Cascade Mtns of WA state

- Tractor

- Kubota B-series & Mini Excavator

Spray arc.

Mainly used in high-speed production work where there's a large volume of weld to be done. So it's a process to get more weld down, in less time. Did I get this right?

Mainly used in high-speed production work where there's a large volume of weld to be done. So it's a process to get more weld down, in less time. Did I get this right?

yomax4

Elite Member

- Joined

- Mar 11, 2007

- Messages

- 2,855

- Location

- Midwest

- Tractor

- ISEKI TA 247. Stihl Saws Gravely Zt's Polaris ATV's State Of The Art Welding Equipment

Partly - check out my post #2 in this thread, pro's AND cons... Steve

Spot On !

Another nice option for High Deposition is Metal Core wire. Not quite as hot as spray but similar results.

Here are some similar links:

- Replies

- 93

- Views

- 19K

![033117_1520[00].jpg 033117_1520[00].jpg](https://www.tractorbynet.com/forums/data/attachments/461/461286-baff7064ba8018623055ffb23fd5a267.jpg)