You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Starting a Barn

- Thread starter Sinecure

- Start date

- Views: 12733

More options

Who Replied?

/ Starting a Barn

#41

I579rbd - Thanks for the comments and good question.

The advantage of the hangers is really ease of installation.

I would have loved to do some true joinery (mortise and tenon), but that is hard to do with built-up LVL's and does require some special tools to get it right. Actually, I guess you could do it with a big drill bit and a chisel, but then you have to factor in the time factor. If I was willing to do that, I probably would have opted for a true post and beam barn build from the start. I really wanted to, but that would have been a significant investment of both time and money.

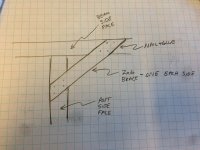

I really don't like the look of the hanger. I know the beam needs some bracing (beam / back down to the post). I am thinking something along the lines of this.

The advantage of the hangers is really ease of installation.

I would have loved to do some true joinery (mortise and tenon), but that is hard to do with built-up LVL's and does require some special tools to get it right. Actually, I guess you could do it with a big drill bit and a chisel, but then you have to factor in the time factor. If I was willing to do that, I probably would have opted for a true post and beam barn build from the start. I really wanted to, but that would have been a significant investment of both time and money.

I really don't like the look of the hanger. I know the beam needs some bracing (beam / back down to the post). I am thinking something along the lines of this.

I know many people will use 3 2x12's with a piece of plywood sandwiched between to make a beam. I thought about this, but opted to go with the LVLs.

My main line of thinking focused around two points:

It is hard to get 3 2x12s that are even (same crown/bow/etc). This would not allow for a true - perfectly straight piece of lumber.

I would have needed to assemble the mocked-up beam on the ground and then install. In all honesty, I would not be able to lift it into place.

With the LVLs, I get a uniform piece of lumber that I am able to lift (one by one) into place. My loader will not reach past the 10 foot height I have the LVLs installed, so I needed to raise them up as high as I can and then manually lift them into the hangers. I was able to do this with the individual LVLs. I am pretty sure I could not have done this with a single beam or built up lumber.

I do pay a price for this however; the LVLs are running me $4.60 a foot.

My main line of thinking focused around two points:

It is hard to get 3 2x12s that are even (same crown/bow/etc). This would not allow for a true - perfectly straight piece of lumber.

I would have needed to assemble the mocked-up beam on the ground and then install. In all honesty, I would not be able to lift it into place.

With the LVLs, I get a uniform piece of lumber that I am able to lift (one by one) into place. My loader will not reach past the 10 foot height I have the LVLs installed, so I needed to raise them up as high as I can and then manually lift them into the hangers. I was able to do this with the individual LVLs. I am pretty sure I could not have done this with a single beam or built up lumber.

I do pay a price for this however; the LVLs are running me $4.60 a foot.

s219

Super Member

- Joined

- Dec 7, 2011

- Messages

- 8,607

- Location

- Virginia USA

- Tractor

- Kubota L3200, Deere X380, Kubota RTV-X

I love working with LVL components -- stays straight and stable a million times better than lumber ever can, which is good for a one-man project where you might not get to button everything down before lumber would start twisting.

Interesting thing I have found with corner braces -- if attached to the inside of the corner, it's very beneficial to be able to notch them in (or even block them in with 2x lumber). Otherwise you are relying on the fastener, usually attached on the diagonal, to do the work, and they can let the brace wiggle/wander. Plus the simple act of snugging-up an un-notched diagonal wants to make it walk (since fastener is on an angle) if you're not careful to snug up each end little by little. So notching or blocking really helps hold it snug.

Inside corner braces can also be attached to post/beam with metal face plates bolted into each, but the labor goes way up.

Another good way to do a corner brace is by face nailing a 2x to each side of the corner, again on a diagonal. You get lots of surface area for the nails to act on, and can put a gob of construction adhesive in there as well. In the end it's very similar to a gusset plate.

Interesting thing I have found with corner braces -- if attached to the inside of the corner, it's very beneficial to be able to notch them in (or even block them in with 2x lumber). Otherwise you are relying on the fastener, usually attached on the diagonal, to do the work, and they can let the brace wiggle/wander. Plus the simple act of snugging-up an un-notched diagonal wants to make it walk (since fastener is on an angle) if you're not careful to snug up each end little by little. So notching or blocking really helps hold it snug.

Inside corner braces can also be attached to post/beam with metal face plates bolted into each, but the labor goes way up.

Another good way to do a corner brace is by face nailing a 2x to each side of the corner, again on a diagonal. You get lots of surface area for the nails to act on, and can put a gob of construction adhesive in there as well. In the end it's very similar to a gusset plate.

S219 - Thanks for the comments. I had planned on rigging up a jig for the router and notching the corner braces into the post and beam, but your comment has got me thinking.

"Corner brace by face nailing a 2x to each side of the corner"

If I am reading your comment correctly, do you mean taking a piece of 2x lumber (2x6 in my case) and essentially mounting a piece on the underside of the beam and then a piece on the vertical post. These would be cut at 45's so when you mounted the corner brace you would essentially have a "triangle" brace assisting to support the beam.

Is my thinking correct? I think I can see it in my head and it may be a better (easier) approach then breaking out the router.

"Corner brace by face nailing a 2x to each side of the corner"

If I am reading your comment correctly, do you mean taking a piece of 2x lumber (2x6 in my case) and essentially mounting a piece on the underside of the beam and then a piece on the vertical post. These would be cut at 45's so when you mounted the corner brace you would essentially have a "triangle" brace assisting to support the beam.

Is my thinking correct? I think I can see it in my head and it may be a better (easier) approach then breaking out the router.

ace10

Silver Member

I would check with manufacturer on extended weather exposure on those LVLs. Especially up on edge like that. We don't know what you're timeline is, but I'm guessing you won't have this weathered in any time soon.

They usually have a coating, but not on the cut ends, and it's not meant to be a permanent weather sealant.

They usually have a coating, but not on the cut ends, and it's not meant to be a permanent weather sealant.

s219

Super Member

- Joined

- Dec 7, 2011

- Messages

- 8,607

- Location

- Virginia USA

- Tractor

- Kubota L3200, Deere X380, Kubota RTV-X

S219 - Thanks for the comments. I had planned on rigging up a jig for the router and notching the corner braces into the post and beam, but your comment has got me thinking.

"Corner brace by face nailing a 2x to each side of the corner"

If I am reading your comment correctly, do you mean taking a piece of 2x lumber (2x6 in my case) and essentially mounting a piece on the underside of the beam and then a piece on the vertical post. These would be cut at 45's so when you mounted the corner brace you would essentially have a "triangle" brace assisting to support the beam.

Is my thinking correct? I think I can see it in my head and it may be a better (easier) approach then breaking out the router.

That's what I would call "blocking" and it will help a lot as you are sandwiching the brace in, and benefiting from nails across the grain from your blocks to your posts (blocks can be oriented with horizontal grain for even stronger results). But I wouldn't put a 45 on the blocks -- I'd leave them with straight cuts and instead put a small chamfer on the diagonal brace (basically blunt off the point of the 45 cut) so that it has a flat "seat" on the block. Then any loads from the brace to the block are going to be normal to the nails. With a 45 on the block, loads would want to peel the block off.

When I said face nailing, I meant take a 2x and nail to each side of the post/beam combo, so the braces are on the outside faces of the corner, like so:

That's also a scenario where nailing across grain with lots of surface area, so they will hold well. This method doesn't look as classy, but it works.

BitChin1

Silver Member

The pic above shows your LVL beam spanning the 16' section (I think).

Which way do you plan to run your joists?

I think the best option would be to have the joists span the 16' direction with the beams spanning the 12' direction to get maximum load capability

Not as good as an engineer but here are a couple of links I use to get direction on these types of questions

Free Beam Sizer - Step 1 of 6

Span Options Calculator for Joists & Rafters

Your might look at Protect-wrap to cover the LVL's from weather as an option.

You definitely need bracing similar to pic in post #43 - many of the post and beam folks cut angles and use large screws for fastening, although notching or side bolting can also work (not sure of the calculations but have a timber framing book that may have the formulas - will check later today)

What are your loft floor loads you expect/want?

Also are you located in a windy area? Any trees that block prevailing wind? these are the types of info you need to determine loads on the building

Which way do you plan to run your joists?

I think the best option would be to have the joists span the 16' direction with the beams spanning the 12' direction to get maximum load capability

Not as good as an engineer but here are a couple of links I use to get direction on these types of questions

Free Beam Sizer - Step 1 of 6

Span Options Calculator for Joists & Rafters

Your might look at Protect-wrap to cover the LVL's from weather as an option.

You definitely need bracing similar to pic in post #43 - many of the post and beam folks cut angles and use large screws for fastening, although notching or side bolting can also work (not sure of the calculations but have a timber framing book that may have the formulas - will check later today)

What are your loft floor loads you expect/want?

Also are you located in a windy area? Any trees that block prevailing wind? these are the types of info you need to determine loads on the building

s219

Super Member

- Joined

- Dec 7, 2011

- Messages

- 8,607

- Location

- Virginia USA

- Tractor

- Kubota L3200, Deere X380, Kubota RTV-X

Good point about loft loads; my friend's barn will hold 40 tons of hay in the loft. That requires very good engineering of the structure and goes beyond stick building techniques I would recommend.

ace10

Silver Member

Easy way to improve the load transference of the LVL beams to the footers is by using jack studs. Just sister on a PT 2X6 to the 6X6 under the Simpson hanger. Still not as good or as pretty as notching, but it'll get the job done.

$0.02

$0.02

sld

Veteran Member

Easy way to improve the load transference of the LVL beams to the footers is by using jack studs. Just sister on a PT 2X6 to the 6X6 under the Simpson hanger. Still not as good or as pretty as notching, but it'll get the job done.

$0.02

Takes the load off the fasteners for sure.

S219 - Thank you for the explanation and the picture. I had always planned on bracing the corner and your comments have given me some different options to think about. Thanks.

Bitchin1 - Great links. I need to play around with those a bit. Actually, I need to have my BIL give me his thoughts. I knew I was going to have to get his advice on some things I am thinking about on the roof, but might as well run some stuff by him with regards to the loft.

I don't plan on storing hay in the loft, but do want it to be sturdy. In all honesty, I had never even considered running the joists across the 16 foot section. I just assumed (maybe incorrectly) that since I would need a beam for the door track I would mount all of the beams going across the center aisle. My current thinking was to then support the joists with the beam and have the joists span the 12 feet between the beams.

Ace10 - I really like the idea of running a 2x6 from the base of the hanger down to the footer. I have seen this done in previous builds and think it makes a lot of sense for this one. It will take some of the load off of the hangers and also allow me to route a notch for my diagonal brace/blocking while they are unmounted (on the ground). Much easier. Thanks.

I did manage to get the rest of the beams up. I now need to start working on the stall top plates.

Bitchin1 - Great links. I need to play around with those a bit. Actually, I need to have my BIL give me his thoughts. I knew I was going to have to get his advice on some things I am thinking about on the roof, but might as well run some stuff by him with regards to the loft.

I don't plan on storing hay in the loft, but do want it to be sturdy. In all honesty, I had never even considered running the joists across the 16 foot section. I just assumed (maybe incorrectly) that since I would need a beam for the door track I would mount all of the beams going across the center aisle. My current thinking was to then support the joists with the beam and have the joists span the 12 feet between the beams.

Ace10 - I really like the idea of running a 2x6 from the base of the hanger down to the footer. I have seen this done in previous builds and think it makes a lot of sense for this one. It will take some of the load off of the hangers and also allow me to route a notch for my diagonal brace/blocking while they are unmounted (on the ground). Much easier. Thanks.

I did manage to get the rest of the beams up. I now need to start working on the stall top plates.

ace10

Silver Member

You are cruising right along despite solo'ing some large sticks of wood. Congrats.

Regarding the angle bracketry and load path.

Here are a couple of pics of my lean-to I built this past winter. With no walls, I had an issue with sway. The posts are 6X6's. The fronts are 16 footers, sunk about 4.5' with rebar drilled through and set in dry concrete.

I had an issue with the front post developing a curve right in the days after I set it. You can see from the pic that one of the 2X12's was not resting on it, so what I did was sister on a 2X6 to carry that load. I glued, screwed and pegged it to the 6X6. I don't have a footer, but you could so something like that under your joist hangers. Maybe stack a couple of 2X6's, arrange them in a decorative way (cut the ends on a 45 or something), then peg them to the post.

And to counteract the side to side sway I used 4X6's. Lagged into beam, and through-bolted on the post to the other bracket. Bolts were crazy expensive. As is all of this hardware, it seems.

Regarding the angle bracketry and load path.

Here are a couple of pics of my lean-to I built this past winter. With no walls, I had an issue with sway. The posts are 6X6's. The fronts are 16 footers, sunk about 4.5' with rebar drilled through and set in dry concrete.

I had an issue with the front post developing a curve right in the days after I set it. You can see from the pic that one of the 2X12's was not resting on it, so what I did was sister on a 2X6 to carry that load. I glued, screwed and pegged it to the 6X6. I don't have a footer, but you could so something like that under your joist hangers. Maybe stack a couple of 2X6's, arrange them in a decorative way (cut the ends on a 45 or something), then peg them to the post.

And to counteract the side to side sway I used 4X6's. Lagged into beam, and through-bolted on the post to the other bracket. Bolts were crazy expensive. As is all of this hardware, it seems.

BitChin1

Silver Member

Be sure to play with the Beam/Joist sizers

Just a quick check shows that the direction you are using now will lead to a loft loading of ~ 60#/sq' (beam limited) and running them the 12' direction you could get 90#/sq' limited by 2x12 joist on 12" spacing - might get more if using engineered joists.

Now in either case 60#/sq' is quite a load, but hay, lumber etc could exceed it. (I did not check all options and made assumptions on what your exact spans are and on what the lvl specs are - so you should do your own calcs with these details).

Can't believe how fast you are moving by yourself!

Have you thought about how you will enclose the building (wood, metal, siding etc)?

Just a quick check shows that the direction you are using now will lead to a loft loading of ~ 60#/sq' (beam limited) and running them the 12' direction you could get 90#/sq' limited by 2x12 joist on 12" spacing - might get more if using engineered joists.

Now in either case 60#/sq' is quite a load, but hay, lumber etc could exceed it. (I did not check all options and made assumptions on what your exact spans are and on what the lvl specs are - so you should do your own calcs with these details).

Can't believe how fast you are moving by yourself!

Have you thought about how you will enclose the building (wood, metal, siding etc)?

EddieWalker

Epic Contributor

Seeing the hangers and that you are putting your beams up on them to create a second story in the middle of the barn has me confused. Why did you go with such tall posts instead of putting the beams on the tops of shorter posts?

I understand you went to a lot of effort and expense to accomplish this, but if it was mine, I would cut those posts and install the beams on top of the posts, then place my joists on top of the beams. Then after getting my second floor decking down, I would stick frame the walls up from there.

Eddie

I understand you went to a lot of effort and expense to accomplish this, but if it was mine, I would cut those posts and install the beams on top of the posts, then place my joists on top of the beams. Then after getting my second floor decking down, I would stick frame the walls up from there.

Eddie

Eddie - Great question and one that I really struggled with during some of my initial thinking / planning.

It really came down to two things. I am not sure that what I was thinking in the planning stages is correct, but here is what I was visualizing.

If the barn was simply a single aisle monitor barn, I would have more than likely gone the route you are suggesting. However, the feature that drew me to this plan in the first place is the front entrance center aisle. It intersects the main center aisle and in my mind I have always visualized the front entrance center aisle being an open two story space. It is hard to see in the last picture I posted, but there is a just under a 22 foot span between the center set of beams. My plans are to have a catwalk that joins the two sections of loft / 2nd floor, but for the most part the front center aisle portion of the barn will be open. I have some crazy idea about fabricating a massive two story barn chandelier that is the focal point once you enter the barn from the front (lol).

Since, I knew I would need the large posts for this section of the barn I just went with them throughout.

The second reason is that I originally wanted to do a true post and beam barn. That idea did not pan out, but I would like to get the most of the post and beam "look" as I can.

Like a said, I am not sure this way of thinking is correct - I may end up with a big wooden stonehenge on my property, but these ideas have so far driven the build.

It really came down to two things. I am not sure that what I was thinking in the planning stages is correct, but here is what I was visualizing.

If the barn was simply a single aisle monitor barn, I would have more than likely gone the route you are suggesting. However, the feature that drew me to this plan in the first place is the front entrance center aisle. It intersects the main center aisle and in my mind I have always visualized the front entrance center aisle being an open two story space. It is hard to see in the last picture I posted, but there is a just under a 22 foot span between the center set of beams. My plans are to have a catwalk that joins the two sections of loft / 2nd floor, but for the most part the front center aisle portion of the barn will be open. I have some crazy idea about fabricating a massive two story barn chandelier that is the focal point once you enter the barn from the front (lol).

Since, I knew I would need the large posts for this section of the barn I just went with them throughout.

The second reason is that I originally wanted to do a true post and beam barn. That idea did not pan out, but I would like to get the most of the post and beam "look" as I can.

Like a said, I am not sure this way of thinking is correct - I may end up with a big wooden stonehenge on my property, but these ideas have so far driven the build.

EddieWalker

Epic Contributor

I understand what you are going for. It's always a hard decision when planning a project on what materials to use. I assumed that you where going with a two story open area down the entire length of the barn when I saw the long posts and was curious how you where going to do this. The good thing is you are not cutting any corners and when it's all said and done, you know that it's going to be there long after your gone.

Eddie

Eddie