You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Strong grapple (last question i promise!)

- Thread starter polemidis

- Start date

- Views: 11747

More options

Who Replied?

/ Strong grapple (last question i promise!)

#21

TMGT

Elite Member

Second, AR is the way to go, could even do 5/16I don't know what machine you are putting this on but I'd seriously consider 1/4" ar400 vs 3/8". Don't waste your time with mild or a-36

Since we have a metric dimension, then I used 10mm material. 10mm Slightly More Than 3/8 inch 0.393.

I have one mistake. if I build things for myself than thicker material than thinner.

After all, you still want yourself a better tool than mass production. Be the thicker and harder before it gets broken. It all depends on what you want him to do. Everything can be broken

I have one mistake. if I build things for myself than thicker material than thinner.

After all, you still want yourself a better tool than mass production. Be the thicker and harder before it gets broken. It all depends on what you want him to do. Everything can be broken

I believe Polemidis has the same goal as I do. Strong yet light grapple. Which is why I asked what machine this is going on. I've Ran a Terex loader with a root rake I could push 24" Dia 60' tall trees over with. When that wouldn't do out came the Hitachi excavator. While the rake on the Terex was nearly indestructible it weighs more than my little 2038 deere tractor does. Wouldn't do much good on the deere. My point is build for the machine. You can over build and not leave enough power to get the work done.

I don't know what alloy Vixr1 used but A36 has a 36ksi yield strength. A572 is 50ksi. Ar400 is 155ksi. More than 3 times the strength, Also has better impact an abrasion resistance. Save the weight, buy the better alloy.

Good luck

I don't know what alloy Vixr1 used but A36 has a 36ksi yield strength. A572 is 50ksi. Ar400 is 155ksi. More than 3 times the strength, Also has better impact an abrasion resistance. Save the weight, buy the better alloy.

Good luck

Guys, I am sorry for the absence, I didn;t realize that the conversations was still going on.

So, I read each post carefully. I have told from the beginning what my goal was. Which is: "OPEN SOURCE"

Meaning yes, I spent 100+ developing it, but I really feel satisfaction if someone use it to build his own, and feel even better if he improves it and also share his improvements.

All the debate about thickness etc, is kind of, personal choices. The design is there, wont need any major modifications to change the width of the plates. I choose 3/8" A572 so far because it is proven and cheap (The 4x8 sheet is only $70 more than the A36). I didn;t know the AR400, I will check its price, and the weldability.

Also one lid vs 2 lids, not a real debate. You will have the design, you can make the lid wider and put only one, again no major modifications there. Same for the distance of the lids, same for the whole width. Right now lid distance is 9", total grapple width is 63".

About the thickness of the square tube, I already bought the 1/8" mainly because the tines are one piece.

Plz be patient for a few days, I am rebuilding my wiki, I will put the design files there, and I would like to write down why we choose each option, plus feedback when we finally build it. So whoever reads it, will be able to do and informed decision on everything.

The firewood processor will go there, as a well drill, and a Compressed Earth Block machine.

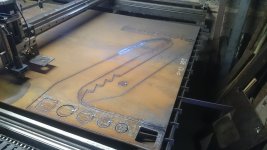

Anyway, I am waiting the federal tax return money in 2 months to build them as I am very low now, and I am slowing down the development as I have to work more hours to get some income. I also haven't complete the CNC plasma so either I have to wait to build the plasma first, or I have to pay $300 cutting service.

I will need some help converting each file to DXF, because some CNC guys that quoted me want to do the nesting on their own.

Since there is some real interest, I will work on the website/design repository more intense, to keep the project going.

Thank you everybody, I had started to think that noone is really interested in

So, I read each post carefully. I have told from the beginning what my goal was. Which is: "OPEN SOURCE"

Meaning yes, I spent 100+ developing it, but I really feel satisfaction if someone use it to build his own, and feel even better if he improves it and also share his improvements.

All the debate about thickness etc, is kind of, personal choices. The design is there, wont need any major modifications to change the width of the plates. I choose 3/8" A572 so far because it is proven and cheap (The 4x8 sheet is only $70 more than the A36). I didn;t know the AR400, I will check its price, and the weldability.

Also one lid vs 2 lids, not a real debate. You will have the design, you can make the lid wider and put only one, again no major modifications there. Same for the distance of the lids, same for the whole width. Right now lid distance is 9", total grapple width is 63".

About the thickness of the square tube, I already bought the 1/8" mainly because the tines are one piece.

Plz be patient for a few days, I am rebuilding my wiki, I will put the design files there, and I would like to write down why we choose each option, plus feedback when we finally build it. So whoever reads it, will be able to do and informed decision on everything.

The firewood processor will go there, as a well drill, and a Compressed Earth Block machine.

Anyway, I am waiting the federal tax return money in 2 months to build them as I am very low now, and I am slowing down the development as I have to work more hours to get some income. I also haven't complete the CNC plasma so either I have to wait to build the plasma first, or I have to pay $300 cutting service.

I will need some help converting each file to DXF, because some CNC guys that quoted me want to do the nesting on their own.

Since there is some real interest, I will work on the website/design repository more intense, to keep the project going.

Thank you everybody, I had started to think that noone is really interested in

jmc

Elite Member

- Joined

- Jul 21, 2003

- Messages

- 3,195

- Location

- SW Indiana

- Tractor

- Ford 1920 4x4 (traded in on Kubota). Case 480F TLB w/4 in 1 bucket, 4x4. Gehl CTL60 tracked loader, Kubota L4330 GST

While you are researching higher strength alloys, you might check what welding does to their yield strength. Most of these designs have welds at the highly stressed locations and in the heat affected zone, the alloy might be no stronger than A36.

While you are researching higher strength alloys, you might check what welding does to their yield strength. Most of these designs have welds at the highly stressed locations and in the heat affected zone, the alloy might be no stronger than A36.

It looks like because the tines are one solid piece, -contrary to some "cheap" designs that have flat bars welded, the weld will not affect the whole integridy that much. They say that preheat is mandatory, as slow cooling. Spot welding also helps to minimize the Heat affected zone. I am not welding expert though. I feel that I will just do the A572, because it is proven and lots of manufacturers are using it. . Hopefully someone with better welding skills -and confidence- than me can try the AR and report back. It may worth the weight savings, maybe one could do 1/4" with AR400??? I have not idea about the cost though...

48x96 x 1/4 AR 400 is $432 delivered to my shop. It would make grapple approximately 30% lighter. It's usually reasonably economical to use better alloys because you don't use as many pounds and end up with better product. I wouldn't worry about the welding too much. 7018 or good name brand er70s-6 (lincoln Hobart esab, no Chinese) will work good on new clean metal. Dual shield if you have it. Don't weld wet or cold steel. Room temp should be fine. Watch your stops for cold cracking. None of the weld joints are too restrained and most are to short welds. 4" is longest weld. If you were worried could split that in two.It looks like because the tines are one solid piece, -contrary to some "cheap" designs that have flat bars welded, the weld will not affect the whole integridy that much. They say that preheat is mandatory, as slow cooling. Spot welding also helps to minimize the Heat affected zone. I am not welding expert though. I feel that I will just do the A572, because it is proven and lots of manufacturers are using it. . Hopefully someone with better welding skills -and confidence- than me can try the AR and report back. It may worth the weight savings, maybe one could do 1/4" with AR400??? I have not idea about the cost though...

A572-50 has a yield of 50,000 lbs AR 400 is usually greater than 140,000.

Manufacturers use a572 because most people think a high number means stronger and they get to say they are using a high strength alloy, and it's economical. Not because it is the best.

48x96 x 1/4 AR 400 is $432 delivered to my shop. It would make grapple approximately 30% lighter. It's usually reasonably economical to use better alloys because you don't use as many pounds and end up with better product. I wouldn't worry about the welding too much. 7018 or good name brand er70s-6 (lincoln Hobart esab, no Chinese) will work good on new clean metal. Dual shield if you have it. Don't weld wet or cold steel. Room temp should be fine. Watch your stops for cold cracking. None of the weld joints are too restrained and most are to short welds. 4" is longest weld. If you were worried could split that in two.

A572-50 has a yield of 50,000 lbs AR 400 is usually greater than 140,000.

Manufacturers use a572 because most people think a high number means stronger and they get to say they are using a high strength alloy, and it's economical. Not because it is the best.

My quote is $447 for the A572 3/8" 4'6"x 8'8", So for the same cost I can save a lot on weight.. Hmm.

I have no stick welder only flux. You think it can be done?

Anyway I have started to upload some stuff to my website. Take a look. You need to download Freecad v0.17 to see them. My wiki is open. If you want to make changes, add pages, upload others designs etc, feel free to do it so.

Open Source Tools

I'm not worried about it. I went and asked some of my friends that build steel barges, I build mostly with aluminum so wanted a second opinion. Was told that if it's going to be a problem it'll break right away. Basically just fall back apart. That has only happened to them when the scraps got mixed up and they didn't know they were using AR scraps. Now these people weld hours every day so their technique is pretty spot on. They told me not to worry but if I wanted to just heat it up around 200 with a temp stick and go at it. It's the rapid cooling that cracks it so don't do it outside in a blizzard. They use dual shield, lincoln 71 elite with co2 gas.My quote is $447 for the A572 3/8" 4'6"x 8'8", So for the same cost I can save a lot on weight.. Hmm.

I have no stick welder only flux. You think it can be done?

Anyway I have started to upload some stuff to my website. Take a look. You need to download Freecad v0.17 to see them. My wiki is open. If you want to make changes, add pages, upload others designs etc, feel free to do it so.

Open Source Tools

Can you run gas and Flux core?

I'm not worried about it. I went and asked some of my friends that build steel barges, I build mostly with aluminum so wanted a second opinion. Was told that if it's going to be a problem it'll break right away. Basically just fall back apart. That has only happened to them when the scraps got mixed up and they didn't know they were using AR scraps. Now these people weld hours every day so their technique is pretty spot on. They told me not to worry but if I wanted to just heat it up around 200 with a temp stick and go at it. It's the rapid cooling that cracks it so don't do it outside in a blizzard. They use dual shield, lincoln 71 elite with co2 gas.

Can you run gas and Flux core?

The flux has its own shield. I can search for specific wire or I can revert the polarity and add a cylinder with CO2 or CO2 with Argon (then its called Mig welding). The weight reduction is too tempting!!! I think I will go with the AR400. I can't wait!!

TMGT

Elite Member

We rebuild a lot of trash truck boxes using Ar400, we use a dual shielded wire, typically lincoln 71m or elite with 75/25 but esab also has some good stuff.

There have been no issues with the duel shielded wires, had some issues in the past using short circuit mig.

There have been no issues with the duel shielded wires, had some issues in the past using short circuit mig.

mmprestine

New member

- Joined

- Nov 4, 2017

- Messages

- 16

- Location

- Green Bay, WI

- Tractor

- Jinma 254XL 4WD FEL Shuttle Shift Y385 engine

There is a problem with downloading the files from open source tools.

Please check as I would like to download the dxf but it only allows me to upload a file.

Please check as I would like to download the dxf but it only allows me to upload a file.

There is a problem with downloading the files from open source tools.

Please check as I would like to download the dxf but it only allows me to upload a file.

The .dxf is not uploaded yet. You can see the link, I put it there so I will not forget it, but there is no file yet(thats why it is red).

If you rush, you can download the 3D Master CAD above, and export the dxf files on your own. I plan to it this weekend. If you do it before then plz edit the page and upload them, it will save me some precious time!