Bobm

Member

- Joined

- Apr 6, 2000

- Messages

- 31

- Location

- Indiana

- Tractor

- Kubota L-5450DT w/ BF-1150A loader & L-4540A backhoe, Kubota B7200HST & RC60-72H mower

Howdy TBN’ers –

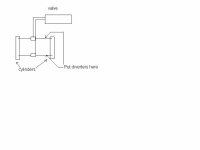

I have a Top N Tilt issue that I don’t believe has been addressed in any of the previous threads concerning TNT or TCC (Terrain Contour Control). My L5450 has Kubota’s TNT installed on it. The entire unit was manufactured for Kubota by Gannon (now Woods). In my case, as per the attached pic, you can see there are dual tilt cylinders as well as the single top link cylinder. The end result (which Bird diligently observed in a past TNT thread) is that the Gannon dual tilt cylinder set-up gives significantly more tilt (9+” measured at end of lower link) than the TCC set-ups. While this is good while using a box scraper, there is a cost…it reduces the lift height of the entire hitch by approximately 5” to 6” for normal (level) implement operations.

When using tilt, the Gannon unit (via single joy stick) provides pressure to one lower link cylinder thereby reducing its effective length. The other lower link cylinder remains passive. When reversing the tilt, there is a detent when the lower links level (both lower cylinders equally extended as in pic) and if continuing to reverse the tilt, the other lower cylinder begins to contract. At no time do both cylinders contract.

For implement applications that don’t use any tilt function, I would like to be able to simultaneously raise BOTH lower link cylinders and thus increase the total lift height of the implement. Is this possible? My solution (not yet attempted) is to disconnect one tilt cylinder from TNT system, connect the same tilt cylinder to my extra remote and thus be able to raise both cylinders albeit in a cobby fashion.

Any suggestions are appreciated. I’m getting tired of taking the entire TNT affair off (and replacing with original top link and bottom connecting arms) when I truly need that last 6” or so of implement lift height.

I have a Top N Tilt issue that I don’t believe has been addressed in any of the previous threads concerning TNT or TCC (Terrain Contour Control). My L5450 has Kubota’s TNT installed on it. The entire unit was manufactured for Kubota by Gannon (now Woods). In my case, as per the attached pic, you can see there are dual tilt cylinders as well as the single top link cylinder. The end result (which Bird diligently observed in a past TNT thread) is that the Gannon dual tilt cylinder set-up gives significantly more tilt (9+” measured at end of lower link) than the TCC set-ups. While this is good while using a box scraper, there is a cost…it reduces the lift height of the entire hitch by approximately 5” to 6” for normal (level) implement operations.

When using tilt, the Gannon unit (via single joy stick) provides pressure to one lower link cylinder thereby reducing its effective length. The other lower link cylinder remains passive. When reversing the tilt, there is a detent when the lower links level (both lower cylinders equally extended as in pic) and if continuing to reverse the tilt, the other lower cylinder begins to contract. At no time do both cylinders contract.

For implement applications that don’t use any tilt function, I would like to be able to simultaneously raise BOTH lower link cylinders and thus increase the total lift height of the implement. Is this possible? My solution (not yet attempted) is to disconnect one tilt cylinder from TNT system, connect the same tilt cylinder to my extra remote and thus be able to raise both cylinders albeit in a cobby fashion.

Any suggestions are appreciated. I’m getting tired of taking the entire TNT affair off (and replacing with original top link and bottom connecting arms) when I truly need that last 6” or so of implement lift height.