My question is why can't Tuff Torq build a tranny that lasts? My JD LA140 has a junk tranny and it has less than a 100 hours on it. I'm planning on using this thread to repair mine this Spring but I'm not happy about it.

Several things...

First, thank you LOGG, great job!

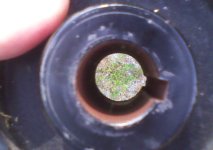

I am getting ready to open up my k46 for the second time. The first time was 2 years ago. Broke the left axle. All the dealers wanted to sell me a new transaxle for around $1,000.... NO!

I contacted TuffTorq directly and got the axle, new filter, and the synthetic fluid delivered for less than $100. After a THOROUGH cleaning internally and replacement of parts it was back in order. In fact it was more responsive with the 5W50 synthetic than the day I bought it new!

Next:

After a lengthy talk with tuff torq in a mindset like this quote from wsp, I have changed my mind! I truly believe they can make great stuff... The OEM's won't buy it! People talk about the bullet proof k66 upgrade... That is a Tuff Torq.

Here was what I found out. The k46 is built to have a drain plug to change fluid... None of the OEMs will pay the extra $.25, yes a quarter!

TuffTorq recommends synthetic oil... The OEMs use conventional

TuffTorq recommends changing the fluid at (if memory serves correctly) 10 hrs, 100 hrs, and then every 200 hrs and the k46 is built to be trouble free for 1,000 hrs! My OEM owners manual did NOT say this, but called it a maintenance free transaxle! This is the 3rd I have seen. It gives TuffTorq a bad name, but the OEMs get to sell more machines because 3 years down the road it's "broken" and might as well go buy a new mower....

If we would have known this from the start and followed these maintenance recommendations, I bet very few of us would have had these problems. But the big box store brands...about anybody competing in the "homeowner" priced mowers won't put the good stuff on, it will cut sales