Hi all,

Im looking into making tyre mats for my neighbours farm. Here is a link to what I am talking about

Unique Inventions Company Ltd, Ballyragget,Kilkenny, supplying labour saving devices for common farmyard and garden chores.

Each tyre mat consists of 45 fasteners and I believe the silage pit will require over 20 mats. If I can make this process fast and easy I will be able to do this job at home and maybe for a few more farmers if the idea works. Taking the tyres off a pit on a cold rainy day in Ireland is no fun so this eliminates getting soaked from the water built up inside the tyres, the possibility of getting infected by vermin urine and the dangers of wires sticking out of badly worn tyres. Id appreciate any suggestions people may have.

What Ive done so far:

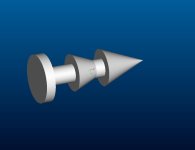

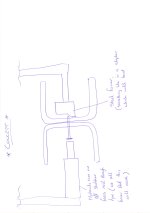

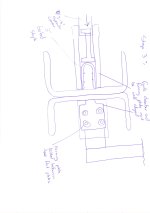

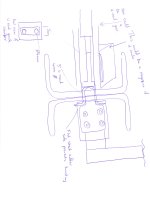

I started out looking at drilling holes in the tyres with a hole saw which worked but it was slow and the wire in the tyre still remained in place which made pushing bolts through difficult. From there my idea moved to punching each tyre with a punch and press. It was then myself and a few colleagues thought of completely eliminating any drilling/punching process. We came up with the idea of pushing the bolt through the tyre like a nail. I machined up a small sleeve with an 8mm internal diameter so that the bolt slid up inside it. The tip was sharpened to 45 degrees (test angle). I made the following rig using some scrap steel and an old hydraulic bottle jack. I tried initially to push the bolt+sleeve through two tyres and found that the tip of the sleeve was not sharp enough to pierce the inside of the tyre. I tested pushing through a tyre starting on the outside and the bolt got pushed through as it got a good grip in the rubber. Therefore with some tuning I think this idea may work. My own thoughts is to make either a lever operated mechanism (bottle jack is a bit slow and to retract it its quite tricky) or use a spring returned single acting air cylinder on a similar rig.

Best Regards,

Ronan

Im looking into making tyre mats for my neighbours farm. Here is a link to what I am talking about

Unique Inventions Company Ltd, Ballyragget,Kilkenny, supplying labour saving devices for common farmyard and garden chores.

Each tyre mat consists of 45 fasteners and I believe the silage pit will require over 20 mats. If I can make this process fast and easy I will be able to do this job at home and maybe for a few more farmers if the idea works. Taking the tyres off a pit on a cold rainy day in Ireland is no fun so this eliminates getting soaked from the water built up inside the tyres, the possibility of getting infected by vermin urine and the dangers of wires sticking out of badly worn tyres. Id appreciate any suggestions people may have.

What Ive done so far:

I started out looking at drilling holes in the tyres with a hole saw which worked but it was slow and the wire in the tyre still remained in place which made pushing bolts through difficult. From there my idea moved to punching each tyre with a punch and press. It was then myself and a few colleagues thought of completely eliminating any drilling/punching process. We came up with the idea of pushing the bolt through the tyre like a nail. I machined up a small sleeve with an 8mm internal diameter so that the bolt slid up inside it. The tip was sharpened to 45 degrees (test angle). I made the following rig using some scrap steel and an old hydraulic bottle jack. I tried initially to push the bolt+sleeve through two tyres and found that the tip of the sleeve was not sharp enough to pierce the inside of the tyre. I tested pushing through a tyre starting on the outside and the bolt got pushed through as it got a good grip in the rubber. Therefore with some tuning I think this idea may work. My own thoughts is to make either a lever operated mechanism (bottle jack is a bit slow and to retract it its quite tricky) or use a spring returned single acting air cylinder on a similar rig.

Best Regards,

Ronan