WranglerX

Super Member

Good a place as any to put this query.

I have a Mahindra rake and a WoodMaxx 62" flail. I've not used either yet. Bought a Harbor Freight QH yesterday after stopping at the local tractor dealer and getting a quote of nearly $550 for a LandPride QH :thumbdown: I won't use it nearly enough to justify that cost.

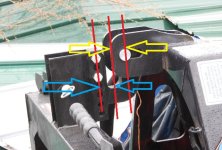

The top hook on the QH is in the top position, looks like if I lower it one pin hole and get the proper Cat1 to Cat 2 bushings it will fit the rake. BUT the vertical distance from the side pins to the top pin on the flail is about 20", the hook just barely touches the flail's top pin (trying things with the QH off the tractor) and it is on the curved part of the hook. The WoodMaxx manual says the flail is Cat 1 QH compatible (but not JD i-match compatible) so either there are no standards for QHs or HF's is way out of spec or WM is way out of spec. The top pin in the flail rides in a horizontal slot, no vertical adjustments possible.

My options:

1. Drill another hole in the QH's top hook, it looks like I could get one in below the current lower hole and the same distance apart as the 2 existing holes. The bottom of the hook would still be below the pin but the pin would hit on the vertical part of the hook.

2. Take the QH back and just suck it up mounting the flail? The rake isn't nearly as heavy so messing around to get the link arms attached wouldn't be as bad as trying to do that with the 700# flail.

Given the OP's original post I've added one possibility:

3: Can I buy a top hook for the QH with a longer "tail" so it can be raised higher than the OEM hook? I don't see anything with a Google search. I have no ability to fabricate anything of that nature. I could make one out of wood be we all know how well that would work out.

Thanks,

Bruce

But there is a standard, just because a manufacturer of implements choose to not follow it and do their own dimensions so only their product line fit their I-match does not make the "standard" wrong or invalid....

Best thing QH manufacturers could have done is follow one standard and probably NOT made top hook adjustable and noted specific necessary clearance around hook area, biggest fault in all this is CHINESE QH... Buy it cheap and spending more money buying new hooks and such to make things fit, where is savings.... Only thing Chinese QH did was make some equipment manufactures look real greedy....

Dale