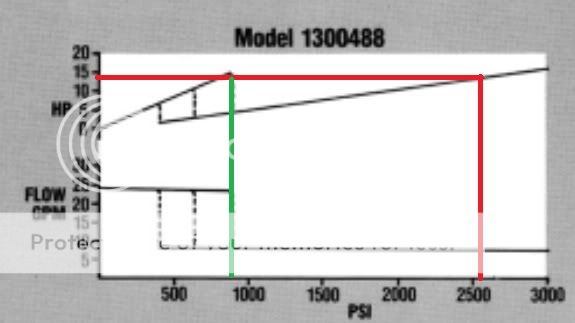

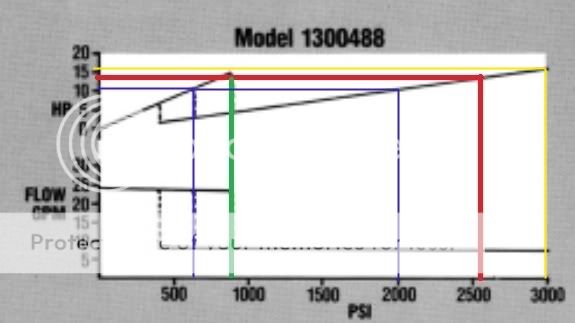

If your pump is shifting and is stalling your 14 hp engine at 2500 psi, that is exactly what the red line in your diagram tells me it should, within 10 - 15%. That's about as close as I would expect under the conditions I would expect on a splitter. Oil viscosity and filter condition (if so equipped) as well as ambient (outside) temperature will all affect oil properties and back pressure.

I agree..

The whole point I was trying to get at was that Northern and Hyd Sirplus are saying that 10-11 hp is OK to use. You'll never see its rated output using that (aside from what IO and TW seem to be getting away with)

Curve calls for ~14 ish HP, but i could never get it reliable with MY 14Hp engine at 2500. I agree there can be outside factors as listed in your post.

Calculation says you can get by with 11.15 Hp@2500 & 6.5 GPM. (2500*6.5)/(1714*0.85) = 11.15 HP

Basically all im saying is follow the curve as the bare minimum and not the calculation when using these pumps, or you'll end up short on HP, doubly so when you start figuring in real world conditions like thick oil and other loads.

This is what burned me. I calculated (and read) ~12Hp to run the pump @2500 reliably. I stepped up a bit and went with a 14Hp engine. I still cant hit 2500 reliably. I really need 18 maybe 20 , in real world conditions.

I did not have the pump performance curve when I bought the pump for my machine. At the time, Barnes Haldex was sold (?) and changed names to Concentric, and all the old links to their manuals were invalid... And search engines hadn't updated to point to the proper place. If I had of seen the chart for the pump prior to purchase I'd never have went with 14 Hp. Probably 18 minimum. The upgrade cost at time of purchase isnt that bad.

Im trying to prevent others from the same issue.