You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Welding table build

- Thread starter CDN Farm Boy

- Start date

- Views: 30803

More options

Who Replied?

/ Welding table build

#61

Shield Arc

Super Member

Oh that's only a small % of the projects I've been on. But who ever thought of taking pictures. :laughing:

OP

CDN Farm Boy

Veteran Member

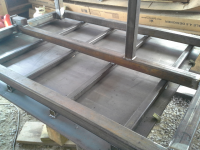

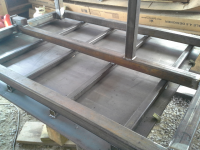

Last night got the main frame tacked together. Keep in mind, this is being built upside down.

The end where the welding shield is will be the cutting end. For now, I have to shift it back and forth on the plate as I'm working. If it weren't for the existing bow in the plate, I wouldn't have the long center support but the extra piece is easy enough to put in now

Practicing my vertical up welding:

Back of the weld: Decent penetration to my untrained eye

The end where the welding shield is will be the cutting end. For now, I have to shift it back and forth on the plate as I'm working. If it weren't for the existing bow in the plate, I wouldn't have the long center support but the extra piece is easy enough to put in now

Practicing my vertical up welding:

Back of the weld: Decent penetration to my untrained eye

OP

CDN Farm Boy

Veteran Member

Arc weld

Veteran Member

I would have made the frame a little differently but as long as it's straight and flat should be fine.

OP

CDN Farm Boy

Veteran Member

I would have made the frame a little differently but as long as it's straight and flat should be fine.

What would you have done different?

The reasons I did it this way may become (hopefully) more apparent as the rest comes together

Thanks for the update with pictures. I look forward to your progress!!!

Ditto :thumbsup:

Will S

Silver Member

- Joined

- Jan 27, 2014

- Messages

- 175

- Location

- DelaWhere?

- Tractor

- John Deere 2032R, 4100; Woods 6215 Mowin'Machine

I would have made the frame a little differently but as long as it's straight and flat should be fine.

I too, am interested in what you would have done, if you were building it. I am ready to buy the rest of the steel for mine (I already have the 28"x48"x 1/2" top). I've looked at so many build threads, and always wonder whether it is better to build a subframe, then weld the legs to the bottom of the frams, or to weld the up the frame tubes to the sides of the legs. I'm also considering whether to use box tubing, or 'C' channel for the frame. But this thread is about CDN Farm Boy's table, which I think is going to be a fantastic table. :thumbsup:

Your thread got me motivated and I was needing a project to test my new Powerarc 300 on.

I went to the steel yard Tuesday and bought a 4x10 sheet of 1/2" plate and 80' of 2.5" x 3/16 square tube. I laid the plate on the shop floor and built the frame on it upside down then flipped it over. Aside from the the metal I bought I added some 2" x 3/16" angle and a piece of pipe in the middle for support. Probably it is overkill but I wanted it sturdy and no flex. Weight of it is about 1400 lbs. I did not add any levelers on the feet or wheels but it sits good and level with no wobble. The thing is nice I don't think you could budge it if you wanted to. I am sure looking forward to being able to work on it and not on the floor anymore. My knees are killing me from this build.

I went to the steel yard Tuesday and bought a 4x10 sheet of 1/2" plate and 80' of 2.5" x 3/16 square tube. I laid the plate on the shop floor and built the frame on it upside down then flipped it over. Aside from the the metal I bought I added some 2" x 3/16" angle and a piece of pipe in the middle for support. Probably it is overkill but I wanted it sturdy and no flex. Weight of it is about 1400 lbs. I did not add any levelers on the feet or wheels but it sits good and level with no wobble. The thing is nice I don't think you could budge it if you wanted to. I am sure looking forward to being able to work on it and not on the floor anymore. My knees are killing me from this build.

Attachments

OP

CDN Farm Boy

Veteran Member

Thanks Will S

Nice table bdog, I'm glad you got the incentive to build your own.

I got the legs and shelf supports tacked together this aft but my FD pager went off and didn't get any pics taken. Hopefully I get home tomorrow with enough daylight to get a bit more done and some more pics.

My main frame is attaching to the side of the legs for reasons you will see as the project continues.

Nice table bdog, I'm glad you got the incentive to build your own.

I got the legs and shelf supports tacked together this aft but my FD pager went off and didn't get any pics taken. Hopefully I get home tomorrow with enough daylight to get a bit more done and some more pics.

My main frame is attaching to the side of the legs for reasons you will see as the project continues.

ishiboo

Platinum Member

Your thread got me motivated and I was needing a project to test my new Powerarc 300 on.

I went to the steel yard Tuesday and bought a 4x10 sheet of 1/2" plate and 80' of 2.5" x 3/16 square tube. I laid the plate on the shop floor and built the frame on it upside down then flipped it over. Aside from the the metal I bought I added some 2" x 3/16" angle and a piece of pipe in the middle for support. Probably it is overkill but I wanted it sturdy and no flex. Weight of it is about 1400 lbs. I did not add any levelers on the feet or wheels but it sits good and level with no wobble. The thing is nice I don't think you could budge it if you wanted to. I am sure looking forward to being able to work on it and not on the floor anymore. My knees are killing me from this build.

Would you mind breaking down the costs on the top and tubing? I'm looking at buying a top from a surplus place. 5' x 11'8" x 1/2" sheet for $700

or a 4' x 8' x 5/8" sheet for $500.

OP

CDN Farm Boy

Veteran Member

My 4' x 5' x 1/2" was a bit under $300 plus taxes. I also looked for used or surplus but found nothing suitable. My whole order was a grand with plan to have a few chunks left over.

OP

CDN Farm Boy

Veteran Member

Looking good!

The hard part looks to be done you should be able to wrap it up in no time. You will love having the table. I have only had mine done a few days and everything is so much easier to do on the table vs rolling around on the floor.

The hard part looks to be done you should be able to wrap it up in no time. You will love having the table. I have only had mine done a few days and everything is so much easier to do on the table vs rolling around on the floor.

Mark @ Everlast

Advertiser

Just be sure not to overweld the top from the backside or you'll have little depressions or bows all over the table. Just scattered light tacking is all that you'll need.

OutbackL130

Silver Member

Wow that was some great info in the previous pages about heat shrinking.

The plates I used to build my tables all had a slight bow in them too, but after I finished the tables were perfectly flat with a 6' straight edge laid on top. 4' x 6' tables I used 3/16" plate with 2" x 1/8" square tube for the frames. 1/2" plate might be more difficult to do this with but if you have strong c clamps it shouldnt matter. To remove the bow, once the frame for the table is built I'd lay the plate on it with the bow down. Then clamp the perimeter of the plate to your frame. If you have cross members in your ladder shape frame it should pull the bow out of the plate and with using 2 1/2" x 3/16" tubing I dont see there being a problem with the frame holding the plate straight after you tack it in. I highly doubt the pressure would distort your frame.

The plates I used to build my tables all had a slight bow in them too, but after I finished the tables were perfectly flat with a 6' straight edge laid on top. 4' x 6' tables I used 3/16" plate with 2" x 1/8" square tube for the frames. 1/2" plate might be more difficult to do this with but if you have strong c clamps it shouldnt matter. To remove the bow, once the frame for the table is built I'd lay the plate on it with the bow down. Then clamp the perimeter of the plate to your frame. If you have cross members in your ladder shape frame it should pull the bow out of the plate and with using 2 1/2" x 3/16" tubing I dont see there being a problem with the frame holding the plate straight after you tack it in. I highly doubt the pressure would distort your frame.

OP

CDN Farm Boy

Veteran Member

A couple hrs yesterday and a couple more this morning and I've got it ready to flip over. Once I got the slag chipped off, my stick weld beads look better than I expected. The plate was stitch welded about 1 1/2" bead on an approx 14 x 24 grid and alternated sides of the tubes to hopefully keep warping to a minimum.

Picked up a new attachment for the air hammer for chipping the slag. Anyone that hasn't tried a needle scaler needs to. Makes the job much easier

I've got about an inch both up and down from flat to adjust for uneven floors

700lbs each greasable wheels

Now to figure out how to flip it over since I can't get to it from the side, only the end......

Picked up a new attachment for the air hammer for chipping the slag. Anyone that hasn't tried a needle scaler needs to. Makes the job much easier

I've got about an inch both up and down from flat to adjust for uneven floors

700lbs each greasable wheels

Now to figure out how to flip it over since I can't get to it from the side, only the end......