You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What am I doing wrong

- Thread starter woodlandfarms

- Start date

- Views: 7957

More options

Who Replied?

/ What am I doing wrong

#11

sd455dan

Super Member

- Joined

- Oct 23, 2012

- Messages

- 6,396

- Location

- North Idaho

- Tractor

- Rhino 554, Ford 550 TLB (JD X500, MTD, Gilson riding mowers) Ford 3000-Sold

In the old days we use to have regulators with heaters built in to them. Just plug a 120-volt extension cord to it. But I haven't seen them in years. You could also hang a mechanic's drop light on the regulator, the heat from the light bulb will help keep the regulator from freezing up.

Thanks, I didn't know that there was actually a purpose built heater for regulators.

In the winter -and unheated shop i don't get to far with the mig due to freezing- even frosting the outside , so i tape a 1200 watt hair dryer to a chair next to the reg.

Hoping the Op can post some pictures of the material and welds, i have mig welded some old unknown type steels before that sure made a mess of the tip.

Migged regular mild steel right next to it, just to prove I wasn't losing my mind:laughing:- and at least in that case, was definitely the metal causing the crud/spatter problem.

IslandTractor

Super Star Member

- Joined

- Sep 15, 2005

- Messages

- 16,647

- Location

- Prudence Island, RI

- Tractor

- 2007 Kioti DK40se HST, Woods BH

For outdoors you may wish to consider gasless fluxcore. Its messy but will save the gas for when you can work inside.

Fluxcore isn't really any messier than stick. MIG and TIG guys get upset because of spatter but frankly it isn't hard to clean up and saves all sorts of grief trying to control gas outdoors. Better penetration too.

Shield Arc

Super Member

One thing to be aware of when switching from Mig to self shielded flux core. Mig guns can not handle self shielded wire. .035" wire will most likely run through a Mig gun OK. .045" wire might if you have a 1/16-inch liner in the Mig gun. 1/16-inch wire or bigger, no way!

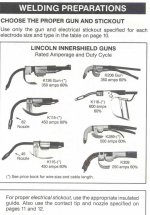

If you are going to run a lot of self shielded wire, get a dedicated self shielded flux core gun. I have had great luck with Lincoln's K-126 guns.

If you are going to run a lot of self shielded wire, get a dedicated self shielded flux core gun. I have had great luck with Lincoln's K-126 guns.

Attachments

sd455dan

Super Member

- Joined

- Oct 23, 2012

- Messages

- 6,396

- Location

- North Idaho

- Tractor

- Rhino 554, Ford 550 TLB (JD X500, MTD, Gilson riding mowers) Ford 3000-Sold

Holy Cow- some of those self shielded wire guns are hard core...

600 amp rating on one of them (k116) - bet with the right supply could lay down some really substantial beads in one pass.

600 amp rating on one of them (k116) - bet with the right supply could lay down some really substantial beads in one pass.

newbury

Super Star Member

- Joined

- Jan 8, 2009

- Messages

- 14,850

- Location

- From Vt, in Va, retiring to MS

- Tractor

- Kubota's - B7610, M4700

OK, so I have learned to Mig Weld via the web. Just being honest here. I am learning a lot, but some things don't make sense.

Wanted to ask you guys why the head of my welder looks this way. I seem to get it gunked up pretty quickly. Am I holding too close (I have to weld outdoors so MIG gas is an issue). Or is this just how after running 24" of weld the thing looks and cleaning is part of the process?

If welding outdoors I thought the general advice was to stick weld. Can your welder do both?

IslandTractor

Super Star Member

- Joined

- Sep 15, 2005

- Messages

- 16,647

- Location

- Prudence Island, RI

- Tractor

- 2007 Kioti DK40se HST, Woods BH

Flux core MIG works fine outdoors. Just as good as stick. As pointed out earlier you are limited to 0.035 gauge wire with standard MIG guns but unless you are welding more than quarter inch steel that is no issue. My stock Miller Passport and Multimatic Kit guns do just fine.If welding outdoors I thought the general advice was to stick weld. Can your welder do both?

Shield Arc

Super Member

I've been on jobs running 70-pounds of wire a day, at over 450-amps with a K-126 gun for months at a time.Holy Cow- some of those self shielded wire guns are hard core...

600 amp rating on one of them (k116) - bet with the right supply could lay down some really substantial beads in one pass.

IslandTractor

Super Star Member

- Joined

- Sep 15, 2005

- Messages

- 16,647

- Location

- Prudence Island, RI

- Tractor

- 2007 Kioti DK40se HST, Woods BH

I've been on jobs running 70-pounds of wire a day, at over 450-amps with a K-126 gun for months at a time.

Probably building things that don't fit on a tractor!!