- Joined

- Aug 31, 2001

- Messages

- 65,912

- Location

- South Bend, Indiana (near)

- Tractor

- Power Trac PT425 2001 Model Year

That's what I ended up doing by removing coupler I guess. I could push ball in be hand and I always move joystick and spool valve. Strange how it wouldn't connect. I did get 90+% work done before dark and tomorrow supposed to rain.

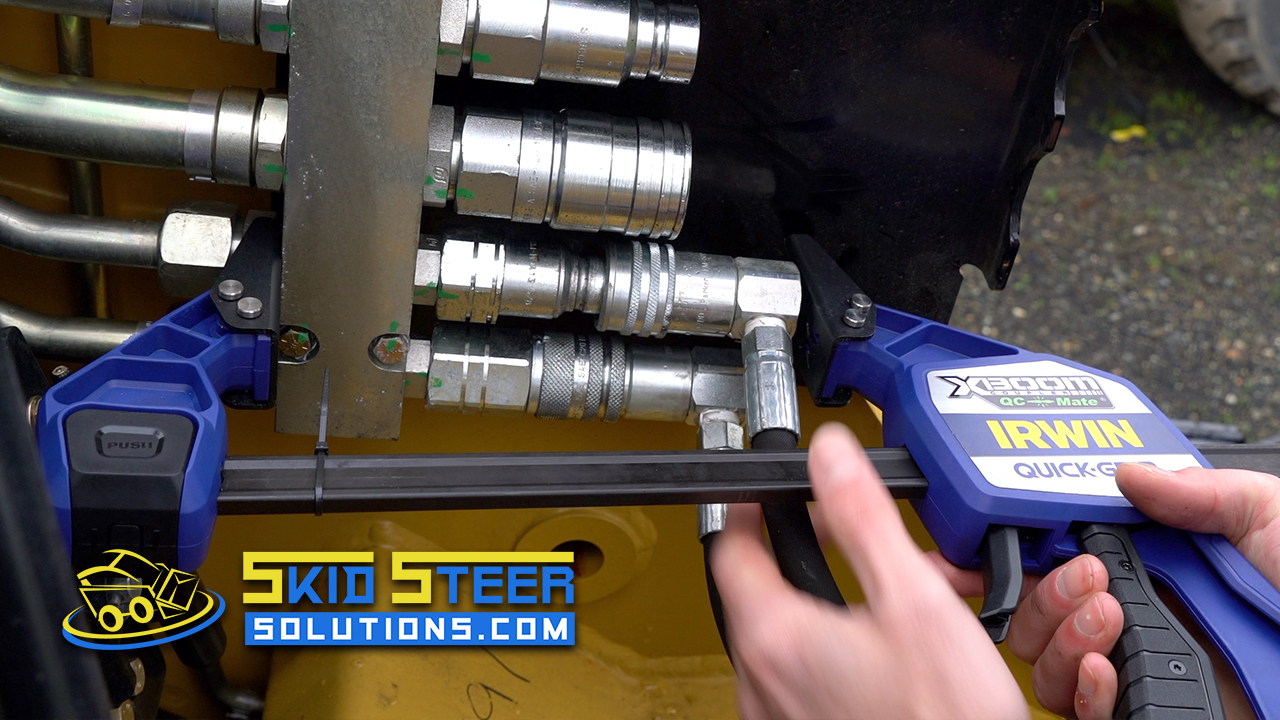

My machine is all hydraulic, so I deal with this fairly often. If I can't push on a connector, I shut off the machine. Grab the implement side of the connector. Take a rag, put it over the ball and connector. Take a flat punch and put it against the ball. Then give the punch a tap with a hammer. One drop of oil comes out, and that's usually enough to get it to connect easily.

If that doesn't work, I repeat the action on the tractor end of the connection. It has never failed to work.

I think it was Bird that may have told me about this maybe 20 years ago.