Today checked the valves, two of them had way more space compared to 0.20 as specified, adjusted them.

Also got all the injectors out, very easy, so I guess Im mister lucky here

One of the bolts was already loose...hmm....not good

The hardest part was to move the second fuel line out of the injector since there is a little too less space if you want to leave the air intake manifold on.

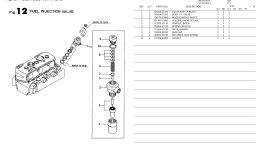

They all look like this:

View attachment 683396

What do you guys think, dirty, very dirty or .....

Also checked the spray patterns, the way the diesel sprayed out, oh boy you cannot call that a pattern at all

Because the tractor is in use these days I put them back and will clean them later.

However the tractor started much better already, so I guess the loose injector made a compression leak.

Any tips on cleaning the injectors?