Agree. I think at worst it might just need more rpm to attain rated output.

If fluid is leaking out of the new valve and it sounds like the pump is straining, that sounds like a pressure restriction somewhere. Maybe open fittings at various points to see if there is pressure where there shouldn't be. But take safety precautions, fluid under pressure is serious.

Thanks for the replies Clemsonfor and California.

In response to the RPM thing, I was running it around 15/1600rpm max when using & testing. In a different thread I read earlier, I believe I saw someone had said 2000-2200rpm for decent speed of the loader.

I have no doubts that there has to be something wrong with the piston seal for the 3 point. I’ve checked to make sure the lock out valve is completely open, and it has been since we discussed that previously.

The PO had it just shy of being turned off. I wish I would have known more about it before purchasing. I would have maybe offered $1,000 for the darn thing if I had known it was going to need all that it has needed. Oh well, it’s my problem now.

I don’t think the leak will stop in the loader valve, but I do agree with there possibly being a pressure restriction somewhere. I plan to crack all the lines loose tomorrow and start the tractor and let it bleed at low RPM for a few seconds to hopefully clear any air out, then turn off and tighten everything.

I know that won’t fix my 3 point issue, but it should help me diagnose loader flow issues.

Then I guess I will see about removing the piston for the 3 point and seeing how all of that looks.

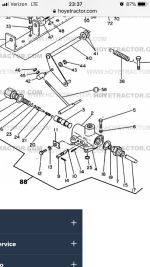

Clemson, you say the “top of the tranmission” I assume you’re referring to the 3 point control valve that the banjo bolt for the HP line goes to? (See first image). If so, I’ve already had this off and apart.

After the engine rebuild, it was stuck solid internally and 3 point was just up. The piston inside of there was stuck. I was able to get it freed up, but there is still (#24 in pic) retained inside the piston. It does appear that it IS supposed to stay in there according to the parts diagram.

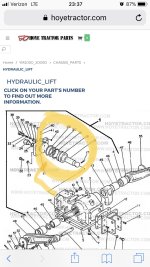

I was referring to removing the piston that is retained behind the lock out valve, and inspecting all of that. (See 2nd image, circled in yellow).